Trend Report – Indoor Ag-Con 2024

JANUARY 14, 2024 — Indoor Ag-Con returns March 11-12 to Caesars Forum offering attendees an insider look into the driving forces behind the ever-evolving vertical farming | greenhouse | controlled environment agriculture industry. Boasting an expanded Expo Hall with 200+ exhibiting companies offering the most cutting-edge products, services and tools on the market, Indoor Ag-Con will offer an immersive experience to farmers, growers, ag tech leaders, suppliers, advocates and enthusiasts.

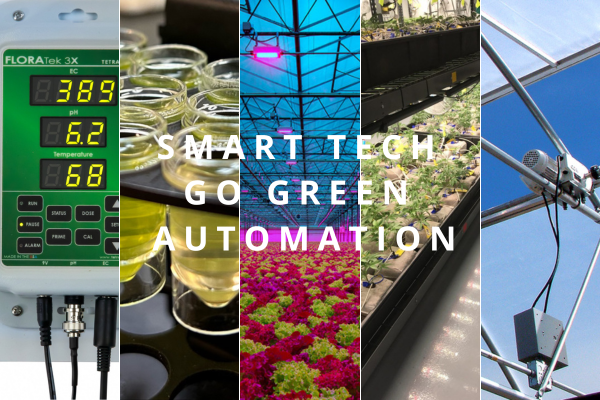

(Photos above from L-R: Tetraponics, New Age Laboratories, Oreon, Lifetime Green Coatings, Climate Control Systems Inc.)

Below are some of the most impactful trends shaping the indoor agriculture industry today and a selection of product highlights from Indoor Ag-Con 2024 exhibitors.

GO GREENER

Sustainability in indoor agriculture is a critical focus in modern farming practices, addressing environmental concerns and promoting efficient resource utilization. Indoor farming allows for precise control over environmental factors such as temperature, humidity, and light, minimizing the need for pesticides and fertilizers. This results in reduced environmental impact compared to traditional outdoor farming. The controlled environment facilitates year-round production, reducing the reliance on seasonal cycles and transportation costs. By incorporating renewable energy sources and implementing innovative technologies, indoor agriculture contributes to a more sustainable and resilient food production system, aligning with the growing global emphasis on environmentally conscious practices.

Key Indoor Ag-Con exhibitors promoting their sustainable focus include:

Lifetime Green Coatings’ (Booth 906) industrial-grade, environmentally friendly concrete floor coating is VOC-free, food-safe, slip-resistant, and easy to apply—making it ideal for any business that handles food, plants, or livestock. 3x as thick as your average epoxy, allowing for durability, while remaining 100% flexible moving with the surface underneath. Create a safer and healthier operational environment with long-lasting, non-toxic coatings that help prevent the growth of mold, mildew, and bacteria.

Oreon (Booth 1320) is a Dutch, innovative developer and manufacturer of high-tech LED grow lights. Oreon started 15 years ago with the first commercial project with water-cooled Oreon LED fixtures installed in 2009. Now, the LED fixtures are worldwide deployed in the horticulture and vertical/indoor farming industry above various types of crops.

Environmental Plant Management (Booth 521) stands at the forefront of eco-friendly plant protection, manufacturing natural solutions in the USA. Their innovative products are distinguished by their use of catalytic enzymes, providing highly effective plant care without the drawbacks of oil, persistent odors, or residues. With 3rd party lab-documented success against a spectrum of pests and diseases, our products represent a leap forward in sustainable and effective plant care. Look out for new products including the 3 in 1 plant wash, ECO Green, an innovative solution that cleans plant leaves, roots, and acts as an effective pest management alternative and Clear Zona, a game-changer in plant yield enhancement.

NEW AGE Laboratories (Booth 1417) is a family-owned and operated business established in 1998 as an environmental laboratory working for clients like NASA and the Dept. of Defense. Their early focus on environmental jobs laid the foundation for a path rooted in scientific innovation and commitment to global betterment. The vision evolved with the world’s agricultural needs leading New Age to be the first Laboratory in North America to offer Plant Sap Analysis. Today, NEW AGE Laboratories stands at the intersection of cutting-edge science and agricultural excellence.

SMART AGRICULTURE

Indoor agriculture’s integration of cutting-edge technologies has allowed farmers to create controlled environments that optimize crop growth and enhance overall productivity. Smart greenhouse construction boasting the latest technologies to increase productivity and sustainability. Additionally, vertical farming, hydroponics, and aquaponics systems leverage technology to maximize space utilization and resource efficiency, reducing the ecological footprint of agriculture. This seamless synergy between technology and indoor agriculture not only ensures year-round crop production but also fosters sustainable farming practices in an increasingly resource-constrained world.

At Indoor Ag-Con, key exhibitors driving the Smart Agriculture trend include:

Agra Tech Greenhouse Manufacturers (Booth 518) specializes in manufacturing commercial greenhouses and related technologies. Their offerings include a variety of greenhouse structures, advanced climate control systems, lighting, fertigation, irrigation, and customization options. Emphasizing energy efficiency and sustainability, Agra Tech caters to a diverse range of clients, from small farms to large commercial growers and educational institutions, providing not only products but also support and consulting services.

Netafim (Booth 1017) strives to provide growers with the best, most effective solutions. They have a total of 70 years of Dutch heritage in glasshouse manufacturing. Along with Netafim’s worldwide presence and precision innovation in the agricultural industry. We ensure that our turnkey commercial greenhouse projects are implemented with our comprehensive agricultural expertise, manufacturing competence, and the latest technology.

Agritecture (Booth 1216) is an advisory services and technology firm focused on climate-smart agriculture, particularly urban and controlled environment agriculture. Their mission is to accelerate and empower the transition to smarter and more resilient agriculture, and our vision is a new era where agriculture is economically feasible, resilient to climate change, and powered by data-driven strategies.

SpectraGrow (Booth 207) offers 3D Plant Lighting for Vertical Farming. They build precision LED systems for controlled environment agriculture. By solving 3D photon uniformity challenges in vertical AgTech, SpectraGrow, uniquely increases farm profitability with less electricity usage, more harvests, greater yields, and better plant quality.

Groupe Eode (Booth 1306) proudly introduces the AgroECU+, the advanced all-in-one grow room HVAC system designed to elevate standards for commercial growers. With a focus on precision temperature and humidity control, remarkable energy efficiency, and the added benefits of ionization through GPS Air NPBItechnology, Group Eode creates an environment that blends optimal conditions for cultivation with a touch of innovation and sophistication. The integration of air diffusion solutions from Aero Textile Concept (ATC), validated for performance using Computational Fluid Mechanics (CFD), further enhances the effectiveness of AgroECU+.

AUTOMATION=LABOR OPTIMIZATION

Automation in indoor farming has further strengthened traditional agricultural practices by integrating cutting-edge technologies to enhance efficiency and precision. In this context, various automated systems are employed to control and monitor crucial factors such as temperature, humidity, light, and nutrient levels within controlled environments. Additionally, artificial intelligence enables real-time data analysis, allowing farmers to make informed decisions for crop management. The implementation of automation not only increases productivity, but also promotes sustainability by minimizing resource waste.

Indoor Ag-Con exhibitors boasting Automation capabilities include:

Thanks to years of experience, Artechno Growsystems (Booth 400) has the know-how, skills, and expertise that benefits customers worldwide. The futuristic technology is not the goal but a means to achieve the best cultivation results. With a plant-oriented approach, technology, and a healthy dose of guts, Artechno Growsystems realizes a new standard within vertical growing with their AVF+. With the fully automated AVF+ Factory, Artechno takes care of all processes for the grower; the input and output of this turnkey plant factory are the same every day. The plants also get everything their plant-hearts desire, such as the right light intensity, temperature, nutrients, CO2, airflow, and humidity.

Grow Director Ltd.(Booth 1319) is a 6-year-old Agri-Tech company offering climate control and automation systems for vertical farms and greenhouses. The system stands out for its modular and scalable design and consists of six independent modules, each to perform its own task, multiple sensors and AI-driven software. It offers multiple solutions, including full hydroponics automation (irrigation, injection, dosing, mixing, water quality control), electrical devices automation (turn on / off, power control), environmental data collection, its analysis and environment control based on it.

Tetraponics (Booth 1416) designs and manufacture hydroponic automation systems. The FLORATek line of automated dosing systems is on its 2nd generation and features a simple user interface, while also featuring enhanced modularity and connectivity. debuting new dosing pumps that will enable the FLORATek 3X to be compatible with any size hydroponic setup. They will also be showing off some commercial-specific capabilities of their online portal, used to remotely monitor and control your systems from anywhere in the world with any device.

Ryzee (Booth 715) provides end-to-end solutions that enable CEA farmers with data-driven automation tools to increase efficiency. Their solutions combine web applications, mobile applications, cloud computing, and IoT sensing and control devices.

Climate Control Systems Inc. (Booth 512) has been manufacturing greenhouse automation systems since 1985. Their CEA automation software and solutions help achieve a better crop while saving precious grower time. Their three main solutions are the Fertigation Manager, Climate Manager and Ozone Pro Water TreatmentSystems. They are also distributors for Watts Water filtration Products and Climate Controls Inc vent motors, rack & pinions that are designed to help CEA owners maximize crop yields, help manage energy costs and help with water & fertilizer conservation.

For more information on the 2024 exhibitors, please see who’s exhibiting here.

ABOUT INDOOR AG-CON:

Founded in 2013, Indoor Ag-Con has emerged as the largest trade show and conference for vertical farming | greenhouse |controlled environment agriculture. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis | hemp, alternate protein and non-food crops. More information, visit www.indoor.ag

Every step of our growing process was designed to limit our impact on the planet. For example, we utilize captured rainwater in our soil-less farming, which results in 90% less water usage than field-grown greens. Plus our greenhouse locations are in regions with high natural precipitation and not dependent on groundwater as the west coast growers do. . Our Devens, MA greenhouse gets 45 inches of rain per year alone and we use all of it, whereas Salinas, California sees only 10 inches of rain per year.

Every step of our growing process was designed to limit our impact on the planet. For example, we utilize captured rainwater in our soil-less farming, which results in 90% less water usage than field-grown greens. Plus our greenhouse locations are in regions with high natural precipitation and not dependent on groundwater as the west coast growers do. . Our Devens, MA greenhouse gets 45 inches of rain per year alone and we use all of it, whereas Salinas, California sees only 10 inches of rain per year. We have always approached growing lettuce as a farming company, rather than a tech company. While we are technologists and our technology is cutting-edge, our priority is growing sustainable, local lettuce that most importantly, tastes great. Our lettuce arrives on grocery store shelves within 24 hours of harvesting, spending less time traveling than most other lettuces. This, in addition to our highly automated system and sustainable growing practices, results in fresh, flavorful leafy greens that remain crispy a remarkably long time after purchase. At the end of the day, we’re growing food. People want to buy and eat what tastes good, and our amazing taste is what’s going to continue to be the differentiator for us. We’ve also grown our business in a way that gives us the ability to scale profitably and better service our retailers, which is going to continue to put us in a position to challenge and compete with field-grown brands as we enter new markets. We’ve surpassed field-grown greens in New England and I’m confident we can replicate that success in other markets across the country as we grow.

We have always approached growing lettuce as a farming company, rather than a tech company. While we are technologists and our technology is cutting-edge, our priority is growing sustainable, local lettuce that most importantly, tastes great. Our lettuce arrives on grocery store shelves within 24 hours of harvesting, spending less time traveling than most other lettuces. This, in addition to our highly automated system and sustainable growing practices, results in fresh, flavorful leafy greens that remain crispy a remarkably long time after purchase. At the end of the day, we’re growing food. People want to buy and eat what tastes good, and our amazing taste is what’s going to continue to be the differentiator for us. We’ve also grown our business in a way that gives us the ability to scale profitably and better service our retailers, which is going to continue to put us in a position to challenge and compete with field-grown brands as we enter new markets. We’ve surpassed field-grown greens in New England and I’m confident we can replicate that success in other markets across the country as we grow. Our business is about farming, and we consider farming a people-based business that puts the crop first. This mindset enables us to recruit the best team of growers, R&D staff, operations staff, and more to carry out our mission of growing fresh leafy greens for all. The farmer-first mindset also reinforces our commitment to growing a product that tastes great and that people actually want to eat, which ties directly to our mission of bringing fresh, leafy greens for all.

Our business is about farming, and we consider farming a people-based business that puts the crop first. This mindset enables us to recruit the best team of growers, R&D staff, operations staff, and more to carry out our mission of growing fresh leafy greens for all. The farmer-first mindset also reinforces our commitment to growing a product that tastes great and that people actually want to eat, which ties directly to our mission of bringing fresh, leafy greens for all. We’ve also expanded our product line to now offer salad kits made with our signature Baby Crispy Green Leaf lettuce, which had an initial launch in the Northeast this fall but will be expanding to our full distribution footprint in January 2024.

We’ve also expanded our product line to now offer salad kits made with our signature Baby Crispy Green Leaf lettuce, which had an initial launch in the Northeast this fall but will be expanding to our full distribution footprint in January 2024.

Our first farm in Wyoming started with a simple mandate: responsibly grow as much food as possible within our community (which has a four-month growing season and imports 90% of the food we eat) and to create job opportunities for people who live in our community, especially ones who suffer overwhelming unemployment rates, like people with disabilities. Our goal was to pursue both missions simultaneously, year-round via indoor growing, and work within the parameters of a city very scarce on available land and with a seasonable economy/labor pool.

Our first farm in Wyoming started with a simple mandate: responsibly grow as much food as possible within our community (which has a four-month growing season and imports 90% of the food we eat) and to create job opportunities for people who live in our community, especially ones who suffer overwhelming unemployment rates, like people with disabilities. Our goal was to pursue both missions simultaneously, year-round via indoor growing, and work within the parameters of a city very scarce on available land and with a seasonable economy/labor pool.

In our 7 years of operation we’ve helped employees open bank accounts, sign their first lease, reverse evictions, get their driver’s license, earn back their guardianships and acted as health advocates as employees work to coordinate care across multiple doctors and health systems. These are real outcomes of our Grow Well customized employment program that we’re intensely proud of….

In our 7 years of operation we’ve helped employees open bank accounts, sign their first lease, reverse evictions, get their driver’s license, earn back their guardianships and acted as health advocates as employees work to coordinate care across multiple doctors and health systems. These are real outcomes of our Grow Well customized employment program that we’re intensely proud of…. We have a roadmap for expansion – in addition to Maine opening and Detroit breaking ground next year, we hope to be announcing another 1 – 2 farms as well. Every farm will share some core features (like the Grow Well model and a commitment to prioritizing local), but also with a level of customization so each farm can adapt to the specific needs of the community they’re rooted in.

We have a roadmap for expansion – in addition to Maine opening and Detroit breaking ground next year, we hope to be announcing another 1 – 2 farms as well. Every farm will share some core features (like the Grow Well model and a commitment to prioritizing local), but also with a level of customization so each farm can adapt to the specific needs of the community they’re rooted in.

From Vertical Farm Daily

From Vertical Farm Daily

As reported in

As reported in