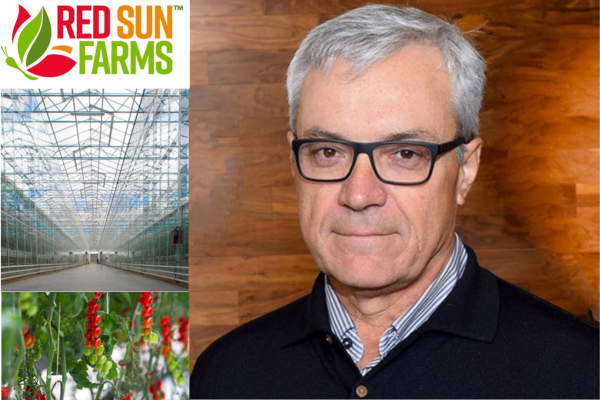

Seed to Plate Approach | Q&A With Red Sun Farms President Jim DiMenna

As one of North America’s largest fully integrated high-tech greenhouse growing operations, Red Sun Farms maintains complete control and ownership of its produce growing and distribution processes. Company President Jim DiMenna will be sharing insights on his company’s “Seed to Plate” approach during the “Scaling Up: Strategies for Successful, Sustainable Business Operation” panel at the upcoming CEA Summit East in Danville, Virginia. Ahead of the event, Indoor Ag-Con had the chance to talk to Jim about Red Sun Farms’ strategy, steady success, operations in Canada, Mexico and the US, and plans for the future in this month’s CEA Q&A.

As one of North America’s largest fully integrated high-tech greenhouse growing operations, Red Sun Farms maintains complete control and ownership of its produce growing and distribution processes. Company President Jim DiMenna will be sharing insights on his company’s “Seed to Plate” approach during the “Scaling Up: Strategies for Successful, Sustainable Business Operation” panel at the upcoming CEA Summit East in Danville, Virginia. Ahead of the event, Indoor Ag-Con had the chance to talk to Jim about Red Sun Farms’ strategy, steady success, operations in Canada, Mexico and the US, and plans for the future in this month’s CEA Q&A.

Can you elaborate on the significance of being one of the largest fully integrated high-tech greenhouse companies in North America? How does this unique positioning contribute to Red Sun Farms’ success and differentiation in the controlled environment agriculture industry?

In addition to being a larger industry player, what truly sets us apart is our vertical integration. We oversee every step of the process – from seed selection, propagation and greenhouse operations to marketing, packing, shipping and distribution – in Mexico, Canada and the USA. This ownership gives us complete control, ensuring exceptional quality, food safety, rich flavor and year-round supply.

Our size and vertical model yield so many benefits and opportunities, including the work we do with seed companies. Given our scale, these companies value conducting trials of their new varieties with us. By operating state-of-the art growing facilities and distribution centers in three countries, we can strategically leverage seasonal differences, emerging as a true 12-month supplier. This allows us to offer customers quicker delivery times and fresher produce.

Speaking of your strong presence in 3 different countries, how does Red Sun Farms manage the challenges of operating across different climates and market dynamics?

Speaking of your strong presence in 3 different countries, how does Red Sun Farms manage the challenges of operating across different climates and market dynamics?

There are any of number of differences and inputs to manage and our highly skilled grower and service teams stay focused on delivering top quality to our customers.

For example, the nuances of heating in Canada differ from those in Mexico. Regardless of location, it’s essential to maintain the greenhouse’s internal temperature above the “dew point” to prevent the onset of disease. Our commitment to high-tech practices within our greenhouses enables us to effectively manage climates and variables across our locations.

Please elaborate on some of the cutting-edge technologies that Red Sun Farms has integrated into your operations and how these technologies have improved sustainability and yield?

Our high-tech greenhouses are intentionally designed for lower environmental impact.

We use biological controls instead of traditional spraying methods, relying on “good bugs” or beneficial insects, to manage pests. Additionally, bumblebees serve as pollinators within our high-tech greenhouses.

As our greenhouses evolve, we’ve adopted higher gutters to enhance circulation. We’re also extracting CO2 from the natural gas we burn, redirecting it to the plants to stimulate growth.

Our commitment to sustainability is evident in our water practices – we continually recycle and reuse water, sending it through drip systems onto rockwool or coco fiber substrates. What the plants don’t use is sterilized, recharged, and returned to the crop, creating a waste-free recirculation loop.

We’ve also implemented a high wire production system to maximize vine plant quality and control. Interestingly, a tomato plant can grow up to 45’ long – the length of a trailer. Prior to high wire growing, tomatoes were harvested when the plants were only 6 feet tall and the tomatoes were not ready. With high wire, the plants are growing up to 10’ feet, enabling waist and eye level harvesting when tomatoes are at their peak

Consumer preferences and market trends in fresh produce are constantly evolving. How does Red Sun Farms stay attuned to these changes, and how do you ensure that your produce meets the expectations of today’s health-conscious and environmentally-conscious consumers?

Consumer preferences and market trends in fresh produce are constantly evolving. How does Red Sun Farms stay attuned to these changes, and how do you ensure that your produce meets the expectations of today’s health-conscious and environmentally-conscious consumers?

We’ve observed continued growth in demand for our snacking pepper, grape tomato, and cucumber offerings. Our beefsteak tomatoes are also highly popular. We remain attentive to market signals and respond accordingly. We are on the side of the angels in a way as our quality, tasty, healthy produce is checking all the boxes for today’s health-conscious consumer.

For example, consider peppers. Not that long ago, green peppers were dominant, but today, red, orange and yellow peppers are the true shining stars. They’re sweeter, tastier, and serve as a guilt-free substitute for chips with dips like hummus.

Our sustainable growing practices resonate with today’s environmentally-conscious consumers.

As mentioned earlier, we’re recycling our water and fertilizer to prevent runoff into lakes and streams, which contributes to issues like algae blooms. We’re also dedicated to developing eco-friendly packaging solutions that prolong food freshness. For example, we’ve replaced the clamshell lid with a film top seal, significantly reducing plastic usage.

What’s next for Red Sun Farms

What’s next for Red Sun Farms

We recently completed a new farm in Manitoba, and are expanding in Mexico as well.

We are always looking for innovative ways to deliver the best to our retail partners and consumers. So technology, automation/labor solutions and equipment innovations, new farm expansions and new growth are always on our radar.

Stay tuned for announcements of future locations of Red Sun Farms greenhouse locations! Meanwhile, to learn more about Red Sun Farms, visit the company website.

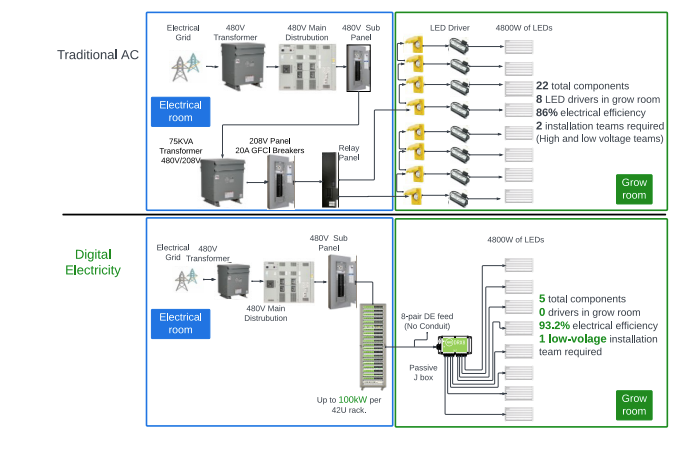

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

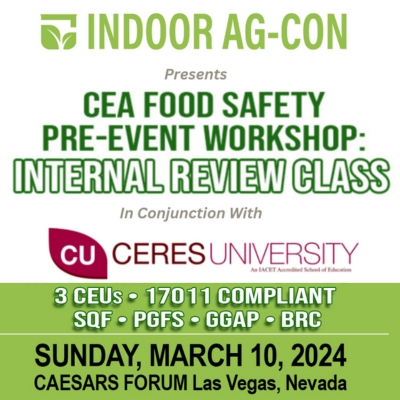

Workshop instructors include Dr. Karl Kolb, president of Ceres University and Ceres Certifications, International (CCI) and Kellie Worrell, GlobalG.A.P. Scheme Manager, CCI. Dr. Kolb is a microbiologist with a quality background and more than 30 years as an industry professional. In addition to her current role with CCI, Kellie Worrell has managed the Food Safety Program for multiple vegetable farms, including a wide variety of crops. CCI features GLOBALG.A.P. among its many GFSI food safety schemes.

Workshop instructors include Dr. Karl Kolb, president of Ceres University and Ceres Certifications, International (CCI) and Kellie Worrell, GlobalG.A.P. Scheme Manager, CCI. Dr. Kolb is a microbiologist with a quality background and more than 30 years as an industry professional. In addition to her current role with CCI, Kellie Worrell has managed the Food Safety Program for multiple vegetable farms, including a wide variety of crops. CCI features GLOBALG.A.P. among its many GFSI food safety schemes.

Harnessing the power of existing genetics and strategic collaborations,

Harnessing the power of existing genetics and strategic collaborations,  Tell us about the main goals and objectives of Sakata Seed’s CEA division? How does it support the needs and demands of greenhouse grower, vertical farm operators and other indoor growers in the sector?

Tell us about the main goals and objectives of Sakata Seed’s CEA division? How does it support the needs and demands of greenhouse grower, vertical farm operators and other indoor growers in the sector? Could you provide a couple of examples of Sakata Seed’s varieties that have shown exceptional performance in indoor growing environments, and what attributes make them well-suited for CEA?

Could you provide a couple of examples of Sakata Seed’s varieties that have shown exceptional performance in indoor growing environments, and what attributes make them well-suited for CEA? Share some insights into the unique challenges and opportunities that CEA presents for seed development and production, compared to traditional outdoor farming?

Share some insights into the unique challenges and opportunities that CEA presents for seed development and production, compared to traditional outdoor farming? How do you identify and prioritize the traits and characteristics that are more important for indoor growers — are you able to collaborate with growers to gather feedback and insights?

How do you identify and prioritize the traits and characteristics that are more important for indoor growers — are you able to collaborate with growers to gather feedback and insights? Can you highlight any recent advancements or innovations in seed development within your CEA division? What varieties or technologies can growers anticipate from Sakata Seed in the near future.

Can you highlight any recent advancements or innovations in seed development within your CEA division? What varieties or technologies can growers anticipate from Sakata Seed in the near future.

The concept of Vertical Farming is not as contemporary as it might seem, with roots plunging deep into ancient history, as far back as the Hanging Gardens of Babylon in 605 BCE. However, it wasn’t until the 20th century that it truly began to blossom as a practical method of farming. The turning point was during WWII, when hydroponics—a subset of Vertical Farming—was employed on a large scale to feed the Allied Forces in the South Pacific, yielding over 8,000 tons of produce. The concept was refined further at Columbia University between 1991 and 1999, under the guidance of Professor Dr. Dickson Despommier. Now hailed as the father of modern Vertical Farming, Despommier and his students successfully devised a way to sustainably feed New York City’s populace via rooftop agriculture, birthing the contemporary approach to multi-story farming.

The concept of Vertical Farming is not as contemporary as it might seem, with roots plunging deep into ancient history, as far back as the Hanging Gardens of Babylon in 605 BCE. However, it wasn’t until the 20th century that it truly began to blossom as a practical method of farming. The turning point was during WWII, when hydroponics—a subset of Vertical Farming—was employed on a large scale to feed the Allied Forces in the South Pacific, yielding over 8,000 tons of produce. The concept was refined further at Columbia University between 1991 and 1999, under the guidance of Professor Dr. Dickson Despommier. Now hailed as the father of modern Vertical Farming, Despommier and his students successfully devised a way to sustainably feed New York City’s populace via rooftop agriculture, birthing the contemporary approach to multi-story farming.