Automated Nutrient Delivery by Nuravine

At Nuravine, our team is dedicated to pushing the boundaries of automated farming. Our vision is to be a component of cities of tomorrow, where large, indoor facilities can grow and process all of the food needed to feed the population. To make this vision a reality, we’ve been working hard to create cutting-edge technology that helps farmers increase efficiency and overcome the challenges they face.

One of the key factors that has helped us achieve our goals has been our participation in the National Science Foundation’s Innovation Corps (ICORPS) program. This program allowed us to travel the country and visit farmers, learn about their challenges, and figure out how we could build technology to solve their current pain points. It was through this program that we discovered the need for better and more affordable ways to run farming facilities, and saw an opportunity to provide farmers with the technology they needed.

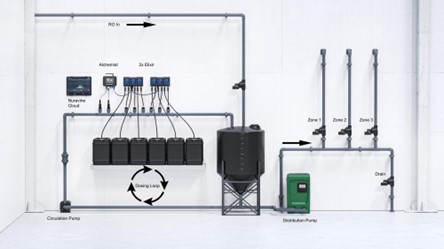

Our flagship product, the Aurora, is a nutrient dosing system that optimizes the performance of recirculating systems for growers. The system includes a smart controller, peristaltic pump modules (Elixirs), and a suite of sensors that measure pH, conductivity, temperature, dissolved oxygen (DO), and oxidation-reduction potential (ORP) of the water in which the plants are living. With its cloud connectivity, growers can monitor real-time conditions of the plants and control the system remotely.

What’s really exciting is that the Aurora is versatile enough to be used in both small and large vertical farms, making it a great solution for a wide range of growers. Our platform is designed to continually improve, and we’re working towards making it a full automation platform that will control lights, HVAC, cameras, and other critical elements of a vertical farm. By making decisions based on multiple variables simultaneously, we believe we can revolutionize the way food is grown.

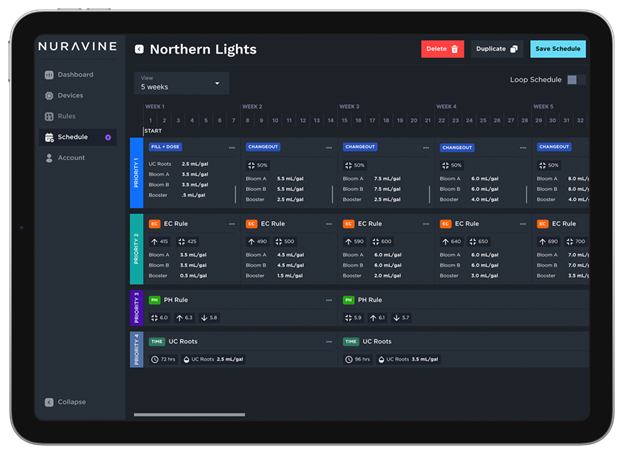

Our newest product, Flux, is a controller that multiplies the functionality of our dosing systems for both recirculating and drain to waste applications. We are also showcasing Nuravine Cloud 2.0, which gives growers an incredible amount of control in an easy to use and intuitive interface.

We are thrilled to be a part of the exciting and rapidly-evolving field of vertical farming. We’ve made it our mission to help farmers overcome the challenges they face and build a more sustainable and efficient future.

For more information check out ourwebsite, follow us on Instagram, or visit us in person at Indoor Ag-Con, booth 424.