Vertical Harvest Farms Secures USDA Loan Guarantee & Maine’s First C-PACE Funding for Industry-leading Project Financing

Deal Recognizes Power of Public-Private Partnerships to Bolster State’s Food System

Vertical Harvest Farms, an indoor farming company focused on customized employment for people with disabilities, is proud to announce the closing of $59.5 million in project financing to develop and operate a 51,000 square-foot hydroponic vertical farm in downtown Westbrook, Maine.

The project is a critical piece of the state’s food system infrastructure and will significantly contribute to the New England Food Vision, where the region’s six states committed to a goal of locally producing 30 percent of the food consumed in the region by 2030 (and 50 percent of the region’s food by 2060), by producing approximately 2.5 million pounds of fresh, leafy greens every year – ranging from mature lettuce, petite greens, microgreens and herbs.

This project also aligns with Vertical Harvest’s “feed locals first” philosophy and goal of providing greens from farm-to-fridge within 24 hours. In this way, the company helps New Englanders avoid the 30 percent loss of nutritional value that occurs within three days of harvest, which widely affects the produce shipped into the region from California, Arizona and abroad. It also significantly helps mitigate food waste by providing longer shelf life and less shrinkage at the retail and institutional level. The company offers these benefits while fulfilling its dual mission to grow food and futures by offering meaningful employment for people with disabilities in this emerging, tech-forward sector.

Vertical Harvest CEO Nona Yehia said, “We’re on a mission to grow food as local, fresh and fair as possible, and ensure there’s a place at the table for everyone in the future of food.”

As the US became a net food importer for the first time ever in 2023, stakeholders are realizing that traditional agriculture is under greater stress from extreme weather, water scarcity and climate change. This has made diversifying food production, leveraging technologic innovations, shortening supply chains, and ensuring access to fresh local food for years to come, imperative. USDA Rural Development recognizes this as well and is incentivizing efforts to future proof the food system.

“As ‘The People’s Department’ we are happy to support fresh food, and good jobs here in Maine, as well as the equity of access to both. USDA Rural Development is committed to building communities and feeding Mainers, and we look forward to Vertical Harvest being a part of the team fulfilling those shared goals,” said USDA Rural Development Maine State Director, Rhiannon Hampson.

This funding also aligns with the CEA Industry’s shift to project-level financing. Vertical Harvest is excited by the public and private partners that made this deal possible.

“We are thrilled to provide financing and partner with Vertical Harvest. Through two pioneer programs from the USDA and other community facilities, we were able to creatively structure this challenging project. We believe this will have a tremendous impact on the local community and the future of food production,” said Alexios Georgousis, Madison One CUSO.

The funding was led by Madison One and Genisys Credit Union and includes $25 million and $23,795,000 loans that utilize USDA Rural Development Business & Industry Loan Guarantees and Rural Energy for America Program (REAP) Renewable Energy and Energy Efficiency Loans, respectively.

This financing is supplemented by a $8,655,189 Commercial Property Assessed Clean Energy (C-PACE) loan – the first in Maine administered by the Efficiency Maine Green

Bank and issued through Nuveen Green Capital – and $2,000,000 of American Rescue Plan (ARPA) funding through the Finance Authority of Maine (FAME).

“We are pleased to have approved Vertical Harvest for this funding through the Efficiency Maine Green Bank in partnership with one of our capital providers, Nuveen Green Capital,” said James Neal, senior manager for finance initiatives at Efficiency Maine. “We strongly encourage more of Maine’s municipalities to follow Westbrook’s example and adopt this ordinance so their local businesses can take advantage of this unique pathway to finance energy improvements, such as upgrading lighting or installing heat pump systems for heating and cooling in their buildings.”

In addition, borrower and partner contributions of $19,189,210 are possible thanks to partners such as Crossroads Impact Corp, Enhanced Capital, Foundation Credit, Waterside Financial, Maine Technology Institute, and others.

“Public-private partnerships benefit a wider group of stakeholders than private capital can alone,” said Enhanced Capital’s Chief Impact Officer and Managing Director Gingee Prince. “In 2017, we partnered with Vertical Harvest to pioneer this space and are excited to see them building even more ambitious capital coalitions today.”

This array of funding follows Vertical Harvest’s model of using public-private partnerships to catalyze resilience within a state’s food system. The company believes this financing model, piloted in Wyoming and now proven in Maine, will pave the way for financing future farms such as the company’s next facility in Detroit, Michigan to be developed in partnership with Bedrock. By bringing together municipal, state and federal funding alongside private capital, not only is the company relocalizing production of perishable produce closer to consumers, but because of Vertical Harvest’s social mission, delivering outsized impact, inclusively.

About Vertical Harvest

Vertical Harvest is a hydroponic, vertical farming company dedicated to community-oriented farms, food and futures. In addition to their passion for local, healthy food grown sustainably, Vertical Harvest also operates on an inclusive, customized employment model with farms designed for accessibility and staffed via hiring practices developed to support meaningful employment for people with disabilities. For more information visit www.verticalharvestfarms.com and sign up for the newsletter, or https://verticalharvestfarms.com/invest-in-vertical-harvest/ to learn about a community raise or follow on socials at @verticalharvestfarms.

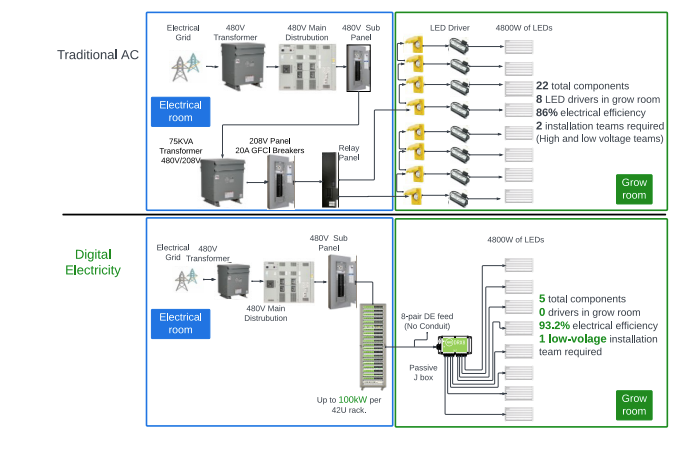

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

Workshop instructors include Dr. Karl Kolb, president of Ceres University and Ceres Certifications, International (CCI) and Kellie Worrell, GlobalG.A.P. Scheme Manager, CCI. Dr. Kolb is a microbiologist with a quality background and more than 30 years as an industry professional. In addition to her current role with CCI, Kellie Worrell has managed the Food Safety Program for multiple vegetable farms, including a wide variety of crops. CCI features GLOBALG.A.P. among its many GFSI food safety schemes.

Workshop instructors include Dr. Karl Kolb, president of Ceres University and Ceres Certifications, International (CCI) and Kellie Worrell, GlobalG.A.P. Scheme Manager, CCI. Dr. Kolb is a microbiologist with a quality background and more than 30 years as an industry professional. In addition to her current role with CCI, Kellie Worrell has managed the Food Safety Program for multiple vegetable farms, including a wide variety of crops. CCI features GLOBALG.A.P. among its many GFSI food safety schemes.

What I find most humorous is that we have been doing it for generations and now is when it is being widely talked about. Sprouting is an ancient practice going back centuries in Asia and the Middle East. All sorts of legumes and other vegetables are sprouted for their digestibility and as a protein and fiber rich food source. Sprouts are the first few days of growth and therefore the origin of all vegetables. The same broccoli sprouts we grow can become full grown heads of broccoli.

What I find most humorous is that we have been doing it for generations and now is when it is being widely talked about. Sprouting is an ancient practice going back centuries in Asia and the Middle East. All sorts of legumes and other vegetables are sprouted for their digestibility and as a protein and fiber rich food source. Sprouts are the first few days of growth and therefore the origin of all vegetables. The same broccoli sprouts we grow can become full grown heads of broccoli. 1930s-1940s. My father started commercially growing in 1978 and I joined the family business full time in 2010. Sprout farms have always been mom and pop or family businesses with tiny budgets and a lot of heart. We were forced to think outside the box and reconfigure equipment or experiment with processes because there were no CEA books to reference and few resources. Even 10 years ago, financial institutions and insurance companies denied our applications or quoted us high interest rates or premiums and asked for collateral because they did not understand CEA or thought it to be a risky investment.

1930s-1940s. My father started commercially growing in 1978 and I joined the family business full time in 2010. Sprout farms have always been mom and pop or family businesses with tiny budgets and a lot of heart. We were forced to think outside the box and reconfigure equipment or experiment with processes because there were no CEA books to reference and few resources. Even 10 years ago, financial institutions and insurance companies denied our applications or quoted us high interest rates or premiums and asked for collateral because they did not understand CEA or thought it to be a risky investment. I am truly amazed at the progress we have made by being creative and innovative without major outside investment (and not that we had much personally to invest either.) It took baby steps and really picking and choosing where to spend funds plus a lot of literal blood, sweat and tears. My father designed and built or modified a lot of the tools and equipment we use out of necessity since not much was out there for C.E.A. or it was too expensive. While it is wonderful that so many are willing to invest in CEA, it is also possible to start on a small scale. Yes, some equipment will be expensive and necessary, but you also do not need to buy all of it or get fancy. We are proof of that.

I am truly amazed at the progress we have made by being creative and innovative without major outside investment (and not that we had much personally to invest either.) It took baby steps and really picking and choosing where to spend funds plus a lot of literal blood, sweat and tears. My father designed and built or modified a lot of the tools and equipment we use out of necessity since not much was out there for C.E.A. or it was too expensive. While it is wonderful that so many are willing to invest in CEA, it is also possible to start on a small scale. Yes, some equipment will be expensive and necessary, but you also do not need to buy all of it or get fancy. We are proof of that.

After successfully guiding

After successfully guiding  We were given the honor and trust to carry out our vision and model for The Villages Grown. This included the strategic direction, design, construction, and operation of a first-of-kind CEA in the South. We backed this with educational programming from both B2C and B2B. We built a community-based brand yet grew enough product for expansion throughout Florida. We worked with beautiful people in a beautiful community.

We were given the honor and trust to carry out our vision and model for The Villages Grown. This included the strategic direction, design, construction, and operation of a first-of-kind CEA in the South. We backed this with educational programming from both B2C and B2B. We built a community-based brand yet grew enough product for expansion throughout Florida. We worked with beautiful people in a beautiful community. Seed2Source launched in 2016 but was really an evolution of my first ‘Agriculture Meets Wellness’ firm which was launched in 2005. Seed2Source is a first-of-kind, Sustainable Agriculture & Wellness, consulting firm headquartered in Florida but serving the US (and beyond). The firm focuses on strategic CEA projects rooted in sustainable agricultural, food-as-medicine, and local food system models.

Seed2Source launched in 2016 but was really an evolution of my first ‘Agriculture Meets Wellness’ firm which was launched in 2005. Seed2Source is a first-of-kind, Sustainable Agriculture & Wellness, consulting firm headquartered in Florida but serving the US (and beyond). The firm focuses on strategic CEA projects rooted in sustainable agricultural, food-as-medicine, and local food system models. The CEA industry is still at its infancy and shall evolve with continuous iterations and innovations. Typically, when most people think of CEA, they only think of High-Tech, AI, Automation, etc. and forget about the State of Agriculture in general. I hope people start to realize that CEA is ‘part’ of a solution and not the ‘only’ solution. Also, I hope that people don’t forget about the actual agriculturists and horticulturists that are the true heroes in creating a sustainable, profitable, CEA operation. This seems to be lost with many of the current players in CEA.

The CEA industry is still at its infancy and shall evolve with continuous iterations and innovations. Typically, when most people think of CEA, they only think of High-Tech, AI, Automation, etc. and forget about the State of Agriculture in general. I hope people start to realize that CEA is ‘part’ of a solution and not the ‘only’ solution. Also, I hope that people don’t forget about the actual agriculturists and horticulturists that are the true heroes in creating a sustainable, profitable, CEA operation. This seems to be lost with many of the current players in CEA. What’s next for you and the team at Seed2Source?

What’s next for you and the team at Seed2Source?

We recently announced the new partnership between

We recently announced the new partnership between  The Virginia Tech-IALR Controlled Environment Agriculture (CEA) Innovation Center was created to leverage the resources of the School of Plant and Environmental Sciences at the College of Agriculture and Life Sciences at Virginia Tech along with the biotechnology, technology, and analytical chemistry capabilities of IALR to move the CEA field forward. The Center offers a one-stop shop for many cutting-edge research projects and is a wonderful vehicle to support and attract industry partners. Part of the initiative is to also serve as a catalyst and hub for CEA companies and technology, and we are already helping to create an ecosystem around CEA innovation with some leading-edge projects in waste recycling, nutrient management, imaging and data analysis, and biotechnology. All of this will be facilitated by the

The Virginia Tech-IALR Controlled Environment Agriculture (CEA) Innovation Center was created to leverage the resources of the School of Plant and Environmental Sciences at the College of Agriculture and Life Sciences at Virginia Tech along with the biotechnology, technology, and analytical chemistry capabilities of IALR to move the CEA field forward. The Center offers a one-stop shop for many cutting-edge research projects and is a wonderful vehicle to support and attract industry partners. Part of the initiative is to also serve as a catalyst and hub for CEA companies and technology, and we are already helping to create an ecosystem around CEA innovation with some leading-edge projects in waste recycling, nutrient management, imaging and data analysis, and biotechnology. All of this will be facilitated by the  We have lots of exciting research projects happening at the moment, both internally to fuel innovation, as well as contract research to support and help solve industry challenges. There are a couple I can mention.

We have lots of exciting research projects happening at the moment, both internally to fuel innovation, as well as contract research to support and help solve industry challenges. There are a couple I can mention. When we launched the Center, one of the many opportunities we were excited about was our ability to leverage our state-of-the-art conferencing center here at IALR to bring industry and academia together through hosting conferences and workshops focusing on CEA. With the CEA industry growing in Virginia, the location of the Summit is near the stakeholders that the Center is striving to serve.

When we launched the Center, one of the many opportunities we were excited about was our ability to leverage our state-of-the-art conferencing center here at IALR to bring industry and academia together through hosting conferences and workshops focusing on CEA. With the CEA industry growing in Virginia, the location of the Summit is near the stakeholders that the Center is striving to serve. The CEA Innovation Center is growing rapidly, and we are always on the lookout for mutually beneficial partnerships in research and education, including contract research opportunities.

The CEA Innovation Center is growing rapidly, and we are always on the lookout for mutually beneficial partnerships in research and education, including contract research opportunities.