Jiffy to Showcase Sustainable, Automation-Ready Solutions at Indoor Ag-Con 2024 | Booth 1012

Jiffy Group looks forward to exhibiting at Indoor Ag-Con March 11-12, 2024, at Caesars Forum Conference Center in Las Vegas.

At Jiffy, we recognize that Controlled Environment Agriculture (CEA) growers are constantly weighing multiple factors when selecting substrate for various hydroponic, aeroponic, and aquaponic systems.

We have worked alongside many CEA growers to help increase cost savings on inputs and reduce costs on labor by offering solutions that are both environmentally sound and easily compatible with automated systems.

Visit us at Indoor Ag-Con Booth #1012 to see our many innovative solutions and allow us to demonstrate how we can help you achieve more efficient and sustainable growing operations.

Streamlining CEA solutions

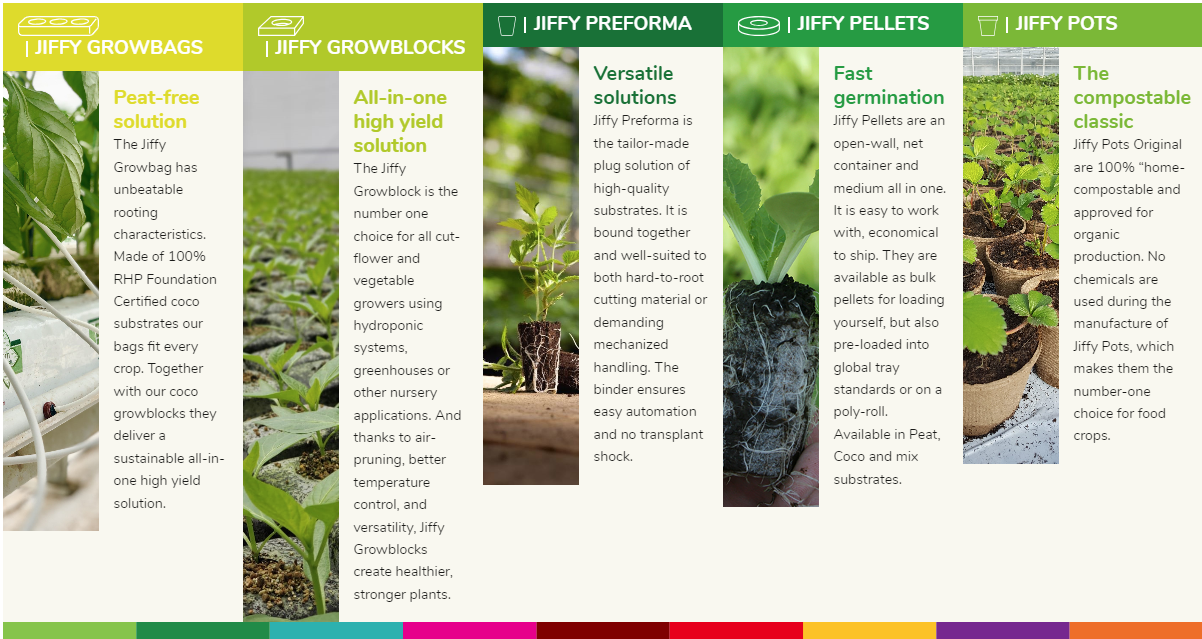

Jiffy’s cost-effective solutions provide the key benefits of helping you attain high germination and yields in a variety of CEA production systems.

Jiffy Pellets and Jiffy Preforma, for example, are cost-effective growing media solutions that are well-suited for leafy greens and herb growers who utilize nutrient film technique (NFT) and deep water culture hydroponic systems.

• Pellets include growing media—either peat, RHP-certified coconut coir, or a mix—in an open wall, and a biodegradable, compostable PLA net. You can purchase pellets in various sizes. Jiffy-7 pellets are shipped dry to save space in storage and maximize freight cost. They then expand upon watering ready for seeding and germination.

• With Preforma, growers can select between multiple peat and coir substrate mixes and tray and dibble sizes. Jiffy designs and formulates Preforma plugs as a ready-to-use growing solution using a substrate binder. This helps the plugs retain optimal physical properties throughout various automated processes such as transplanting.

For growers producing vine crops or strawberries in gutter-based systems with drip irrigation, we recommend our Growbags (including EasyFill Growbags) or loose fill mixes.

Jiffy also offers other products to help with your needs, such as Jiffy Growblocks, which are a great combination with Growbags. Jiffy Pots are the preferred choice for growers with hydroponics systems because they offer several key benefits, not only related to crop quality and quantity but also contribute to the sustainability and profitability of operations.

As you work with us to fulfill your substrate needs, you will also benefit from our global supply chain and sales force, advanced handling of raw materials, and certifications ensuring success at every step.

Adhering to the highest standards

At Jiffy, we prioritize the safety, sustainability, and quality of our products and processes.

Our production facilities are certified with various ISO certification standards: ISO 22000 for food safety, ISO 14001 for sustainability, and ISO 9001 for quality. All our operations are also compliant with California’s Proposition 65. These certifications ensure that the media provided is of the highest quality produced to specifications that allow for optimal results.

For some products and production locations, Jiffy has obtained the quality mark from RHP, the nonprofit European knowledge center for growing media, certifying that raw materials and products meet strict quality and sustainability standards. We also offer a range of OMRI listed organic, 0% plastic, and peat-free solutions helping you to achieve your sustainability goals.

Let’s work together

Opportunities abound for the CEA industry to feed an expanding global population, and Jiffy is glad to assist growers by offering them many customized solutions.

As we further our commitment to the industry, we will be opening a new Preforma factory on the West Coast of the United States in Fall 2024.

We look forward to working with you to make sure your operation is a continued success. Come visit us at Indoor Ag-Con Booth #1012, and let’s grow together.

Klasmann-Deilmann

Klasmann-Deilmann Nygaia is the substrate solution of the future that will soon be able to completely replace conventional substrates, e.g. in the cultivation of leafy vegetables in hydroponics and vertical cultivation systems. The innovative substrate fibre consists of 60% natural, bio-based raw materials and is completely biodegradable.

Nygaia is the substrate solution of the future that will soon be able to completely replace conventional substrates, e.g. in the cultivation of leafy vegetables in hydroponics and vertical cultivation systems. The innovative substrate fibre consists of 60% natural, bio-based raw materials and is completely biodegradable. This means it produces neither waste nor microplastics. The Nygaia substrate fibre for hydroponics is inert, salt-free and provides a perfect water retention capacity. It also offers very good air capacity, which optimally supports healthy root growth of plants. Nygaia is a product development of the close collaboration of Klasmann-Deilmann and Maan Biobased Products.

This means it produces neither waste nor microplastics. The Nygaia substrate fibre for hydroponics is inert, salt-free and provides a perfect water retention capacity. It also offers very good air capacity, which optimally supports healthy root growth of plants. Nygaia is a product development of the close collaboration of Klasmann-Deilmann and Maan Biobased Products.

Hydrofarm Holdings Group, Inc.

Hydrofarm Holdings Group, Inc.

We recently announced the new partnership between

We recently announced the new partnership between  The Virginia Tech-IALR Controlled Environment Agriculture (CEA) Innovation Center was created to leverage the resources of the School of Plant and Environmental Sciences at the College of Agriculture and Life Sciences at Virginia Tech along with the biotechnology, technology, and analytical chemistry capabilities of IALR to move the CEA field forward. The Center offers a one-stop shop for many cutting-edge research projects and is a wonderful vehicle to support and attract industry partners. Part of the initiative is to also serve as a catalyst and hub for CEA companies and technology, and we are already helping to create an ecosystem around CEA innovation with some leading-edge projects in waste recycling, nutrient management, imaging and data analysis, and biotechnology. All of this will be facilitated by the

The Virginia Tech-IALR Controlled Environment Agriculture (CEA) Innovation Center was created to leverage the resources of the School of Plant and Environmental Sciences at the College of Agriculture and Life Sciences at Virginia Tech along with the biotechnology, technology, and analytical chemistry capabilities of IALR to move the CEA field forward. The Center offers a one-stop shop for many cutting-edge research projects and is a wonderful vehicle to support and attract industry partners. Part of the initiative is to also serve as a catalyst and hub for CEA companies and technology, and we are already helping to create an ecosystem around CEA innovation with some leading-edge projects in waste recycling, nutrient management, imaging and data analysis, and biotechnology. All of this will be facilitated by the  We have lots of exciting research projects happening at the moment, both internally to fuel innovation, as well as contract research to support and help solve industry challenges. There are a couple I can mention.

We have lots of exciting research projects happening at the moment, both internally to fuel innovation, as well as contract research to support and help solve industry challenges. There are a couple I can mention. When we launched the Center, one of the many opportunities we were excited about was our ability to leverage our state-of-the-art conferencing center here at IALR to bring industry and academia together through hosting conferences and workshops focusing on CEA. With the CEA industry growing in Virginia, the location of the Summit is near the stakeholders that the Center is striving to serve.

When we launched the Center, one of the many opportunities we were excited about was our ability to leverage our state-of-the-art conferencing center here at IALR to bring industry and academia together through hosting conferences and workshops focusing on CEA. With the CEA industry growing in Virginia, the location of the Summit is near the stakeholders that the Center is striving to serve. The CEA Innovation Center is growing rapidly, and we are always on the lookout for mutually beneficial partnerships in research and education, including contract research opportunities.

The CEA Innovation Center is growing rapidly, and we are always on the lookout for mutually beneficial partnerships in research and education, including contract research opportunities.

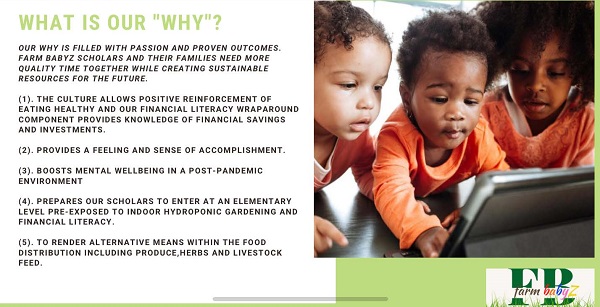

farm babyZ LLC, a STEM.org Reviewed ™ organization, has created and packaged an educational hydroponic growers curriculum and American-made merchandise/grow kit for early childhood development agencies and other educators working with children between the ages of two to five years old.

farm babyZ LLC, a STEM.org Reviewed ™ organization, has created and packaged an educational hydroponic growers curriculum and American-made merchandise/grow kit for early childhood development agencies and other educators working with children between the ages of two to five years old.

Sensei Ag CEO Sonia Lo will lead the Indoor Ag-Con keynote presentation, “Improving Human Wellness One Farm At A Time,” on Monday, October 4, 2021 from 11:30 am – 12:20 pm. A headliner event at the October 4-5, 2021 edition at the Hilton Orlando, Lo’s discussion will focus on Sensei Ag’s form factor agnostic approach to building and expanding indoor farms.

Sensei Ag CEO Sonia Lo will lead the Indoor Ag-Con keynote presentation, “Improving Human Wellness One Farm At A Time,” on Monday, October 4, 2021 from 11:30 am – 12:20 pm. A headliner event at the October 4-5, 2021 edition at the Hilton Orlando, Lo’s discussion will focus on Sensei Ag’s form factor agnostic approach to building and expanding indoor farms.

Being form factor agnostic is core to Sensei Ag’s business model and growth plan. We are indoor growers – not just greenhouse growers, not just vertical farm growers. With that said, it’s not just about the types of leafy greens and other produce we will be able to grow using different form factors, but also the ability to venture into new regions of the globe, areas that were traditionally considered food deserts but through one form factor or another can now become food oases.

Being form factor agnostic is core to Sensei Ag’s business model and growth plan. We are indoor growers – not just greenhouse growers, not just vertical farm growers. With that said, it’s not just about the types of leafy greens and other produce we will be able to grow using different form factors, but also the ability to venture into new regions of the globe, areas that were traditionally considered food deserts but through one form factor or another can now become food oases. myself down the line. That said, after spending the majority of my career in finance and tech, I can truly say that I am the happiest growing local, nutritious food for others. I joined Sensei Ag last April for the once-in-a-lifetime opportunity to spearhead a company developing science focused on human wellness from food and agriculture systems. As CEO, I am very honored to lead an exceptionally talented team of professionals who together share one vision and that is to increase adoption of indoor agricultural production globally.

myself down the line. That said, after spending the majority of my career in finance and tech, I can truly say that I am the happiest growing local, nutritious food for others. I joined Sensei Ag last April for the once-in-a-lifetime opportunity to spearhead a company developing science focused on human wellness from food and agriculture systems. As CEO, I am very honored to lead an exceptionally talented team of professionals who together share one vision and that is to increase adoption of indoor agricultural production globally. Nevertheless, the journey thus far has been incredible. I’ve never been known to take the straight and narrow path. Ask anyone about the twisted, curvy roads on Lana’i. Yet, in my mind, there’s never been a more crucial time in our world’s history to address global food insecurity, to encourage and develop new means of promoting health and wellness and to heal and nourish our planet. I look forward to the adventure that lies ahead.

Nevertheless, the journey thus far has been incredible. I’ve never been known to take the straight and narrow path. Ask anyone about the twisted, curvy roads on Lana’i. Yet, in my mind, there’s never been a more crucial time in our world’s history to address global food insecurity, to encourage and develop new means of promoting health and wellness and to heal and nourish our planet. I look forward to the adventure that lies ahead.