AGEYE Technologies CEO Nick Genty Talks Profitability, AI and the Future of Indoor Farming With HYVE Partnership

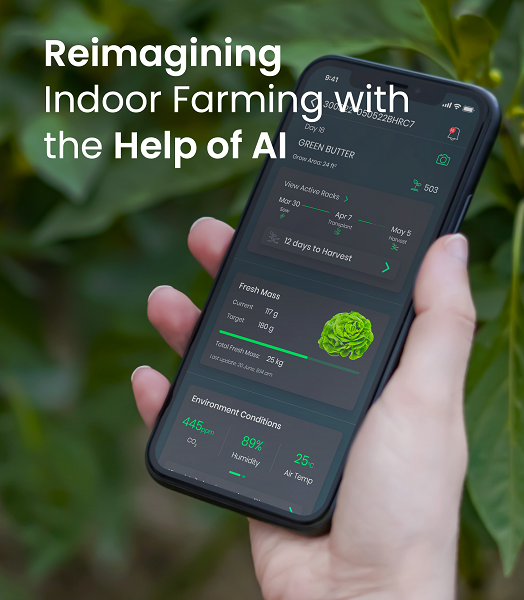

As the indoor farming industry continues to grow, the need for profitability remains a significant challenge for commercial growers. AGEYE Technologies is helping lead the way in automated platform monitoring for vertical farms and greenhouses and CEO Nick Genty provides insight into how they are addressing this challenge, as well as their advancements in AI and machine learning. In this month’s CEO Q&A Nick also talks about AGEYE’s new partnership with HYVE Indoor Farming Systems, their recently announced indoor farm project in Nebraska and future growth plans.

What is one of the biggest challenges facing the indoor farming industry today and how is AGEYE working to address it.

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised.

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised.

How does AGEYE stay ahead of the curve when it comes to advancements in AI and machine learning, and what impact do these technologies have on your monitoring platform?

AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable.

AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable.

Can you tell us more about the partnership between AGEYE and HYVE Indoor Farming Systems- – How did this collaboration come about and what are the main benefits the partnership will bring to commercial growers?

Our first introduction actually happened at a previous Indoor Ag-Con. There are a lot of moving parts in this industry, and things change so rapidly. It’s easy to be sucked in by what might turn out to be smoke and mirrors, but there was something about our initial meeting with HYVE that led us to believe there was substance backed by significance and passion.

The combination of automation, crop intelligence, exceptional hardware and lighting – it all seemed like it was there. It was evident that we both had tangible evidence and proof of concept for what we could do on our own, but more importantly, together. Collaboration has often been a theme in this industry and we could see early on that we complemented each other well in areas where one might not be as strong as the other. We both had experiences apart and we shared and leveraged those experiences on an early trial project together. This project proved to us both that we really felt that the sum of our parts was greater than what it should have been – almost like adding 1 + 1 to get 3.

For our customers and prospects, the main benefits are just immense. We believe that we have a revolutionary turnkey system that combines the absolute best in hardware, lighting, infrastructure, software, and AI controls and monitoring. These are some very tangible attributes. What we also think is a huge benefit is our flexibility in what we do. We have scalable systems and feel invested in the commercial farmer as if it were our own money. We see a pathway to profitability for the commercial farmers we work with by being a ‘right-sized’ entity with experience to back what we say we can do. Our methodology removes much of the guesswork and mitigates some of the risks that growers encounter. It’s really an exciting time to be invested together in a partnership where we share such diverse talent sets, system integrity, and vision for what indoor farming can become.

What challenges do you anticipate in building the new indoor farm in Nebraska, and how will AGEYE work with HYVE to overcome them?

There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

One of the very essential things we seek to do is to create a system that can produce a saleable product for our customers each and every day in a cost-effective way. The process has to be repeatable and successful. Profitability is always the challenge and without good market data and an efficient distribution methodology that includes an understanding of the market, there isn’t a way to get there. We’re not in the business of just selling equipment so that people fail. For this reason, we will be assisting the client in Nebraska with some expertise in understanding the market opportunities. We will help them look at the product mix and provide relevant data that puts them on a path to see a return on their investment.

Looking ahead, what other types of project or collaborations do you see as possibilities for AGEYE and HYVE and how do you envision your partnership evolving in the future?

AGEYE and HYVE are both really good at very distinct and yet dissimilar things that together can produce great results. One of the things we talked about even early on was how we were both so innovative and solutions-based, which we highlight in our joint tagline of ‘Matched Innovation. Unmatched Solutions.’ We believe that together we can offer solutions that others really can’t, and much of it is not only the very real and measurable tangible evidence of our quality and system intelligence but also the passion and knowledge of the people involved.

Looking forward HYVE will include the AGEYE platform as a very critical and integrated piece of the puzzle for growers. We’ll look at each individual project and see where the marriage of automated functionality and artificial intelligence makes both logistical and financial sense for the grower and our respective companies.

We also will likely look at each respective strength and ability in the stand-alone entities. For instance, it might make sense for one entity to capitalize on technical support from the other because of specific expertise that resides within a certain sector. We truly believe that at the end of the day, our common mission is about creating a system that makes the most sense for the grower in an economic and qualitative sense.

For more information, visit the AGEYE Technologies website.

In September of 2022 Plenty announced plans to build the world’s largest indoor vertical farm campus near Richmond, VA. Can you share more details on this exciting project?

In September of 2022 Plenty announced plans to build the world’s largest indoor vertical farm campus near Richmond, VA. Can you share more details on this exciting project?

In your opinion, what are the key challenges that the CEA/Vertical Farm industry must overcome?

In your opinion, what are the key challenges that the CEA/Vertical Farm industry must overcome? What’s next for Plenty?

What’s next for Plenty?

Earlier this year, Crop One and its partner Emirates Flight Catering celebrated the opening of ECO 1 (Emirates Crop One), the world’s largest vertical farm in Dubai. Can you share a little about your mission and goals for this incredible new facility?

Earlier this year, Crop One and its partner Emirates Flight Catering celebrated the opening of ECO 1 (Emirates Crop One), the world’s largest vertical farm in Dubai. Can you share a little about your mission and goals for this incredible new facility? During Indoor Ag-Con, you’ll be participating in our “Food Security Through CEA” panel. What is one of the key messages you hope to share during this session?

During Indoor Ag-Con, you’ll be participating in our “Food Security Through CEA” panel. What is one of the key messages you hope to share during this session? Crop One sells its fresh, local produce to 30+ US retail stores under the FreshBox Farms brand. Your marketing for the brand highlights Crop One’s “ Plants First” ™ approach. What is that and why is an important part of your messaging?

Crop One sells its fresh, local produce to 30+ US retail stores under the FreshBox Farms brand. Your marketing for the brand highlights Crop One’s “ Plants First” ™ approach. What is that and why is an important part of your messaging?

After successfully guiding

After successfully guiding  We were given the honor and trust to carry out our vision and model for The Villages Grown. This included the strategic direction, design, construction, and operation of a first-of-kind CEA in the South. We backed this with educational programming from both B2C and B2B. We built a community-based brand yet grew enough product for expansion throughout Florida. We worked with beautiful people in a beautiful community.

We were given the honor and trust to carry out our vision and model for The Villages Grown. This included the strategic direction, design, construction, and operation of a first-of-kind CEA in the South. We backed this with educational programming from both B2C and B2B. We built a community-based brand yet grew enough product for expansion throughout Florida. We worked with beautiful people in a beautiful community. Seed2Source launched in 2016 but was really an evolution of my first ‘Agriculture Meets Wellness’ firm which was launched in 2005. Seed2Source is a first-of-kind, Sustainable Agriculture & Wellness, consulting firm headquartered in Florida but serving the US (and beyond). The firm focuses on strategic CEA projects rooted in sustainable agricultural, food-as-medicine, and local food system models.

Seed2Source launched in 2016 but was really an evolution of my first ‘Agriculture Meets Wellness’ firm which was launched in 2005. Seed2Source is a first-of-kind, Sustainable Agriculture & Wellness, consulting firm headquartered in Florida but serving the US (and beyond). The firm focuses on strategic CEA projects rooted in sustainable agricultural, food-as-medicine, and local food system models. The CEA industry is still at its infancy and shall evolve with continuous iterations and innovations. Typically, when most people think of CEA, they only think of High-Tech, AI, Automation, etc. and forget about the State of Agriculture in general. I hope people start to realize that CEA is ‘part’ of a solution and not the ‘only’ solution. Also, I hope that people don’t forget about the actual agriculturists and horticulturists that are the true heroes in creating a sustainable, profitable, CEA operation. This seems to be lost with many of the current players in CEA.

The CEA industry is still at its infancy and shall evolve with continuous iterations and innovations. Typically, when most people think of CEA, they only think of High-Tech, AI, Automation, etc. and forget about the State of Agriculture in general. I hope people start to realize that CEA is ‘part’ of a solution and not the ‘only’ solution. Also, I hope that people don’t forget about the actual agriculturists and horticulturists that are the true heroes in creating a sustainable, profitable, CEA operation. This seems to be lost with many of the current players in CEA. What’s next for you and the team at Seed2Source?

What’s next for you and the team at Seed2Source?