Jiffy to Showcase Sustainable, Automation-Ready Solutions at Indoor Ag-Con 2024 | Booth 1012

Jiffy Group looks forward to exhibiting at Indoor Ag-Con March 11-12, 2024, at Caesars Forum Conference Center in Las Vegas.

At Jiffy, we recognize that Controlled Environment Agriculture (CEA) growers are constantly weighing multiple factors when selecting substrate for various hydroponic, aeroponic, and aquaponic systems.

We have worked alongside many CEA growers to help increase cost savings on inputs and reduce costs on labor by offering solutions that are both environmentally sound and easily compatible with automated systems.

Visit us at Indoor Ag-Con Booth #1012 to see our many innovative solutions and allow us to demonstrate how we can help you achieve more efficient and sustainable growing operations.

Streamlining CEA solutions

Jiffy’s cost-effective solutions provide the key benefits of helping you attain high germination and yields in a variety of CEA production systems.

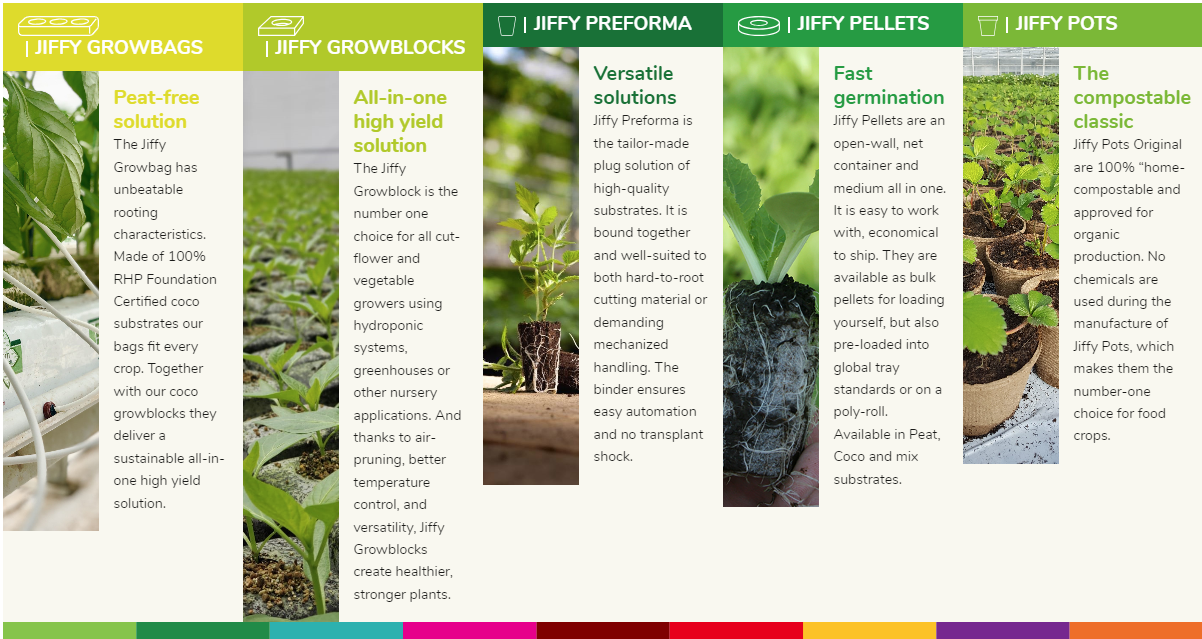

Jiffy Pellets and Jiffy Preforma, for example, are cost-effective growing media solutions that are well-suited for leafy greens and herb growers who utilize nutrient film technique (NFT) and deep water culture hydroponic systems.

• Pellets include growing media—either peat, RHP-certified coconut coir, or a mix—in an open wall, and a biodegradable, compostable PLA net. You can purchase pellets in various sizes. Jiffy-7 pellets are shipped dry to save space in storage and maximize freight cost. They then expand upon watering ready for seeding and germination.

• With Preforma, growers can select between multiple peat and coir substrate mixes and tray and dibble sizes. Jiffy designs and formulates Preforma plugs as a ready-to-use growing solution using a substrate binder. This helps the plugs retain optimal physical properties throughout various automated processes such as transplanting.

For growers producing vine crops or strawberries in gutter-based systems with drip irrigation, we recommend our Growbags (including EasyFill Growbags) or loose fill mixes.

Jiffy also offers other products to help with your needs, such as Jiffy Growblocks, which are a great combination with Growbags. Jiffy Pots are the preferred choice for growers with hydroponics systems because they offer several key benefits, not only related to crop quality and quantity but also contribute to the sustainability and profitability of operations.

As you work with us to fulfill your substrate needs, you will also benefit from our global supply chain and sales force, advanced handling of raw materials, and certifications ensuring success at every step.

Adhering to the highest standards

At Jiffy, we prioritize the safety, sustainability, and quality of our products and processes.

Our production facilities are certified with various ISO certification standards: ISO 22000 for food safety, ISO 14001 for sustainability, and ISO 9001 for quality. All our operations are also compliant with California’s Proposition 65. These certifications ensure that the media provided is of the highest quality produced to specifications that allow for optimal results.

For some products and production locations, Jiffy has obtained the quality mark from RHP, the nonprofit European knowledge center for growing media, certifying that raw materials and products meet strict quality and sustainability standards. We also offer a range of OMRI listed organic, 0% plastic, and peat-free solutions helping you to achieve your sustainability goals.

Let’s work together

Opportunities abound for the CEA industry to feed an expanding global population, and Jiffy is glad to assist growers by offering them many customized solutions.

As we further our commitment to the industry, we will be opening a new Preforma factory on the West Coast of the United States in Fall 2024.

We look forward to working with you to make sure your operation is a continued success. Come visit us at Indoor Ag-Con Booth #1012, and let’s grow together.