Climate Control, Smart Irrigation, Healthy Super Food

(Photos L-R from Hoogendoorn, FabricAir, NGS, Pure Life Carbon and Dramm)

Indoor Ag-Con returns March 11-12 to Caesars Forum Las Vegas offering attendees an insider look into the driving forces behind the ever-evolving vertical farming | greenhouse | controlled environment agriculture industry. Boasting an expanded Expo Hall with 200+ exhibiting companies showcasing the most cutting-edge products, services and tools on the market, Indoor Ag-Con will offer an immersive experience to farmers, growers, ag tech leaders, suppliers, advocates and enthusiasts.

As a follow-up to Indoor Ag-Con Trend Report One issued earlier this year, below are some of the latest trends shaping the indoor agriculture industry today and a selection of product highlights from Indoor Ag-Con 2024 exhibitors.

Climate Control

In recent years, climate control has emerged as a pivotal trend in indoor agriculture, revolutionizing the way crops are grown in controlled environments. With a heightened focus on sustainability and food security, growers are increasingly turning to sophisticated climate control systems to optimize growing conditions regardless of external weather patterns. These systems integrate advanced technologies such as sensors, automated ventilation, and LED lighting, to create tailored environments that mimic ideal growing conditions. By fine-tuning factors like temperature, humidity, CO2 levels, and light intensity, indoor farmers can achieve higher yields, faster growth cycles, and superior crop quality while conserving resources and minimizing environmental impact.

Groupe Eode, (Booth 1306) in partnership with ECU Plus, ATC, and GPS, offers a comprehensive precision climate solution, assisting growers in increasing yields while minimizing risks and energy costs. The ECU plus is a new product line offering a HVAC system capable of delivering the most precise temperature and humidity control in the industry, with exceptional energy efficiency. GPS is a new product line reducing and controlling mildew and pathogen by generating ions in the space. Cost effective and without any maintenance or replacement parts.

Hoogendoorn Growth Management’s (Booth 600) flagship product, IIVO, is a revolutionary climate computer equipped with Intelligent Algorithms, streamlining greenhouse management. IIVO not only simplifies climate optimization but also stands out with proactive Intelligent Algorithms that continuously fine-tune climate control based on forecasted weather conditions, ensuring peak efficiency in greenhouse operations.

Microclimates (Booth 701) is an innovative technology firm specializing in environmental automation tailored for the controlled agricultural sector. In an era where automation systems often operate independently, lacking seamless communication, Microclimates introduces a groundbreaking solution. Unlike traditional siloed approaches, the platform transcends hardware dependencies, providing a unified ecosystem. Through the platform, disparate systems—ranging from climate control and lighting to irrigation and fertigation—are seamlessly integrated onto a single user-friendly interface, facilitating harmonized data management and optimal operational efficiency. Microclimates partnered with Veea Inc. to launch LoRaWAN (Long Range Wide Area Network) as the wireless solution for sensing and controlling and its low price point allows for easy deployment in any facility.

DryGair (Booth 207) develops and manufactures a patented dehumidification solution for commercial-scale horticulture, including greenhouses, nurseries, indoor grow rooms, drying rooms, and more. DG dehumidifiers combine powerful and efficient dehumidification with a unique air circulation mechanism to ensure uniform, optimal conditions in the grow space.

DesertAire (Booth 1305) offers highly efficient, purpose built integrated HVACD equipment specifically designed for indoor agriculture. Desert Aire’s GrowAire™ GreenAire™ and DriCure™ HVACD solutions provide integrated HVAC control of temperature and humidity in order to provide stable VFD to enhance and protect crops. The new Chilled Water Integrated HVACD System for CEA will be shown at Indoor Ag-Con.

FabricAir (Booth 702) provides complete air solutions for indoor farming and vertical grow operations. Their fabric-based air delivery systems are custom engineered to prevent microclimates, facilitate uniform temperature and humidity within the grow space, and allows plants to flourish through every stage of the grow cycle. FabricAir ducts are lightweight, hygienic, washable, and they don’t condensate which eliminates corrosion issues. The Rack Flow system offers custom designed airflow solutions for multi-tiered grow spaces.

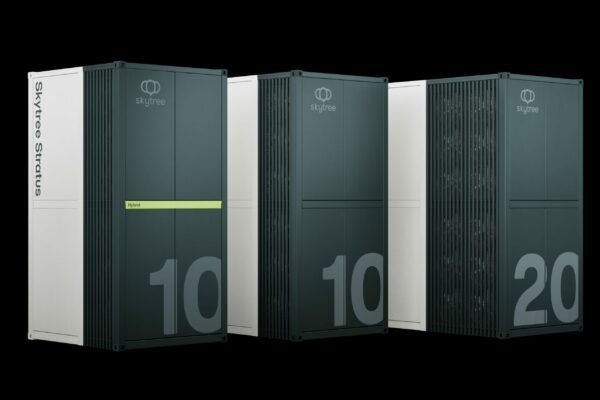

A new partnership between Wageningen University & Research and Skytree (Booth 903), focuses on the use of direct air capture (DAC) technology in the Dutch horticulture industry. The project aims to explore how DAC-generated CO2 can affect plant growth, the energy efficiency of producing CO2, and the optimal integration of DAC into existing greenhouses.

- Quality: The project investigates the impact of DAC-generated CO2 on plant growth, which is crucial for greenhouse quality improvements.

- Energy: It measures the energy required to produce 1kg of CO2, a key factor in the sustainability of greenhouse operations.

- Integration: The research focuses on optimizing DAC integration, which is essential for modernizing greenhouse infrastructure.

MJ–Tech (Booth 320) is a leader in providing high-pressure fog systems, from breeding to propagation and/or cultivation. To manage humidity, to have adiabatic cooling (lower temperatures) all in the most flexible way with your overall climate computer steering.

Smart Irrigation

Irrigation in indoor agriculture has undergone a notable transformation, driven by advancements in technology and a growing emphasis on sustainability and efficiency. Traditional irrigation methods, such as flood and drain systems or hand-watering, are being replaced by more precise and automated techniques. Hydroponic and aeroponic systems, utilizing nutrient-rich solutions or misting mechanisms, have gained popularity due to their ability to deliver water directly to plant roots while minimizing waste. Moreover, the integration of sensors, data analytics, and smart controls enables growers to monitor and adjust irrigation schedules in real-time, optimizing water usage and crop health. This shift towards precision irrigation not only conserves water, but also enhances crop yields and quality in indoor farming environments.

Dramm (Booth 613) is pleased to announce their partnership with CE-Line to provide in-line nutrient testing to irrigation water in North America. CE-Line is a unique, laboratory quality, nutrient analysis system that automatically samples water throughout the day. This in-line testing solution provides accurate data within an hour, eliminating the wait for test results from a remote laboratory. Sample results are securely stored in the cloud with APIs available to connect to your climate control and fertigation systems. This connectivity allows for automated optimization of nutrient levels in real-time.”

In the Controlled Environment Agriculture (CEA) sector, Siemens’ (Booth 1400 and 1501) advanced controls systems, innovative infrastructure, and building automation systems empower growers to optimize crop growth, conserve resources, and increase yields—all while harnessing the power of automation and data-driven insights—leaving customers more sustainable, from the field to the table.

FGM USA (Booth 321) offers automated NFT growing systems including all irrigation and water treatment systems, as well as a propagation/vertical grow system manufactured by FGM. FGM a Danish and USA Company is a leading designer and mfg. of horticulture equipment since 1979.

HANS® (Booth 1522) has reinvented every component used to treat water – from the redundant pump to reverse osmosis elements into intelligent, efficient, space-saving devices. They are designed to work together in modular, scalable systems to meet every need. So even if your customers have brackish water, or need de-ionized water, or use a million gallons per day, HANS components can be assembled to get the job done – quickly, easily and effectively.

Super Food

Indoor agriculture presents a promising avenue for exploring alternate food sources, particularly in the realm of sustainable and innovative farming practices. Vertical farms, hydroponics, and aquaponics systems are just a few examples revolutionizing how we grow food. These methods not only maximize space but also offer opportunities to cultivate unconventional crops like microgreens, edible flowers, and specialty herbs. As indoor agriculture continues to evolve, it provides a fertile ground for experimenting with diverse food sources, offering resilience against climate change and bolstering food security for future generations.

Pure Life Carbon (Booth 1222) is a private Canadian clean AgTech firm that has developed the first re-usable, carbon sequestering, soilless growing medium for the controlled environment agriculture market. The products utilize Advanced Carbon technology to solve problems for growers that were unsolvable in the past. Pure Life Carbon is among a high-performing group of global innovators and visionaries working to feed the populations of tomorrow while healing the environment. Pure Life Carbon has developed the first re-usable, carbon sequestering, soilless growing medium for the controlled environment agriculture market.

Klassman-Dielmann’s (Booth 812) focus will be on the presentation of a genuine innovation for modern horticulture: Nygaia. Nygaia is a new and groundbreaking substrate fiber based on biopolymer technology that is biodegradable and is particularly suitable for use in hydroponic systems. Under the theme “The magic of innovation,” the completely newly developed, innovative substrate solution will be brought to life with plant examples grown in Nygaia, test kits distributed to interested guests at the Klassman-Dielmann booth or with the appearance of magician Rob Anderson during the Indoor Ag-Con Expo Floor Day One Cocktail reception!

Royal Gold (Booth 505) is the Original Coco soils company, pioneering Coconut based soils and growing mediums for nearly 2 decades. They are leaders in quality and consistency in the marketplace and focus on industry leading customer support for both hobby and commercial cultivation of all crops. Featuring a variety of soils and soilless mediums and offering OMRI/CDFA organic fertilizers and amendments, Royal Gold is the gold standard in gardening. They will be displaying the new All-purpose fertilizer and new 70/30 Coco-Perlite Blend as well as sharing information on its forthcoming Planting Mix and Potting and Propagation Mix.

BIO520 (Booth 1212) is an all-natural essential liquid mineral nutrient for optimal plant cultivation. Derived from a combination of ancient volcanic magma and sea sediments, and free of any harmful chemicals, BIO520 contains an abundance of vital minerals to help plants thrive. BIO520 is beneficial for all plants and crops, indoor or outdoor. Developed from Mother Nature for Mother Nature.

NGS (Booth 1023) manufactures hydroponics for Strawberries, Lettuces and Leafy Greens. NGS is an engineering firm which has been developing automated systems to optimize growing production both by reducing labor and by incrementing production. NGS builds greenhouses that grow lettuce in the desert as well as indoor systems for strawberries. NGS is presenting its patented rotational system for strawberries which doubles normal tabletop production. This new system is revolutionizing the way strawberries are being grown while reducing labor and production costs.

Supreme Perlite (Booth 1216) horticultural perlite products are the ideal indoor, CEA, or hydroponic growing media made here in the U.S.A from domestic raw material sources. The products are sterile, 100% natural, non-toxic, lightweight, pH neutral, durable and insulating. Used as a standalone product, expanded perlite offers clear advantages such as excellent capillarity, water-holding capacity, and air-filled porosity. Combined with other media, perlite boosts drainage rates and aeration, holds moisture and nutrients close to roots, and resists compaction as other substrates begin to break down.

EPM (Booth 521) stands at the forefront of eco-friendly plant protection, manufacturing natural solutions in the USA. They excited to debut a 3in1 plant wash, ECO Green, an innovative solution that cleans plant leaves, roots, and acts as an effective pest management alternative. Its unique blend of catalytic enzymes and citric acid not only removes dirt and biofilm but also guards against pests.

For more information on the 2024 exhibitors, please visit www.indoor.ag.

ABOUT:

Founded in 2013, Indoor Ag-Con has emerged as the largest trade show and conference for vertical farming | greenhouse |controlled environment agriculture. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis | hemp, alternate protein and non-food crops. More information, visit www.indoor.ag

##

Once installed onsite, Stratus captures CO2 from the ambient air to be deployed to enrich crop yield and increase productivity. The fully modular nature of Stratus allows for multiple units to be combined into a “Skytree Stratus Hub” to meet larger volume needs. Through partnerships, Skytree offers local liquefaction of CO2, required for storage of liquid CO2, enabling CEA businesses to continuously capture and store CO2 in use during peak production periods.

Once installed onsite, Stratus captures CO2 from the ambient air to be deployed to enrich crop yield and increase productivity. The fully modular nature of Stratus allows for multiple units to be combined into a “Skytree Stratus Hub” to meet larger volume needs. Through partnerships, Skytree offers local liquefaction of CO2, required for storage of liquid CO2, enabling CEA businesses to continuously capture and store CO2 in use during peak production periods.

In a groundbreaking debut at

In a groundbreaking debut at  Sollum Technologies designed the only 100% dynamic LED lighting solution that modulates the full spectrum of the Sun’s natural light to illuminate closed environments such as greenhouses, research centers and laboratories. Sollum’s award-winning, turnkey solution consists of internet of things, AI-powered light fixtures that are controlled by Sollum’s proprietary SUN as a Service® cloud platform.

Sollum Technologies designed the only 100% dynamic LED lighting solution that modulates the full spectrum of the Sun’s natural light to illuminate closed environments such as greenhouses, research centers and laboratories. Sollum’s award-winning, turnkey solution consists of internet of things, AI-powered light fixtures that are controlled by Sollum’s proprietary SUN as a Service® cloud platform.

Hands-on Learning – Removable trays in workstations promote hands-on learning for crop planting, nurturing, and harvesting.

Hands-on Learning – Removable trays in workstations promote hands-on learning for crop planting, nurturing, and harvesting.

“When people think of dehumidification, they think of mold prevention”, Miller says. “But it’s much more than that. Maintaining an ideal relative humidity range, coupled with a uniform climate (thanks to DryGair’s patented air circulation mechanism), has a major impact on the crop. It creates an active climate that stimulates growth and improves quality.”

“When people think of dehumidification, they think of mold prevention”, Miller says. “But it’s much more than that. Maintaining an ideal relative humidity range, coupled with a uniform climate (thanks to DryGair’s patented air circulation mechanism), has a major impact on the crop. It creates an active climate that stimulates growth and improves quality.”

Once growers understand that this tool can both improve yields and reduce costs, it’s an easy decision,” he adds.

Once growers understand that this tool can both improve yields and reduce costs, it’s an easy decision,” he adds.