CEA Alliance Applauds Introduction of Bipartisan Senate Bill to Scale Supply Chain Loan Guarantee Program at USDA

Read the full story from HortiDaily …

Read the full story from HortiDaily …

Harvest Today is on a mission to transform local food cultivation, one wall at a time. From addressing food insecurity to building collaborative partnerships and embracing sustainability, the company is driven by a commitment to practical change. In this month’s CEA Q&A, Director of Global Sales and Marketing Peter Maher sheds light on the company’s straightforward approach to simplify, empower and revolutionize local food cultivation through its innovative Harvest Wall systems.

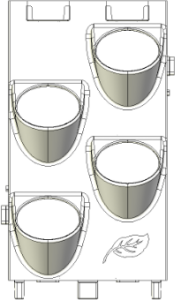

When developing the Harvest Wall, we had two objectives – maximize plant count per square foot and make growing SIMPLE – The Harvest Wall achieves both.

When developing the Harvest Wall, we had two objectives – maximize plant count per square foot and make growing SIMPLE – The Harvest Wall achieves both.

Farming, in and of itself is a simple concept – plant, grow, harvest – repeat. Though we all know it’s never that simple, especially indoors, that’s really what it comes down to.

The Harvest Wall Vertigation™ System was developed with the idea of simplicity always top of mind.

Every aspect of the wall was purposefully designed with the user in mind — from the stackable grow tiles, that make the grow system more economical for manufacturing and shipping, offer the best plant density per square foot available and are able to fit in any shape/size grow space — to the patented Vertigation™ System and flood rail, providing precision fertigation and eliminating the need for emitters.

Each Harvest Wall comes ready to go and is equipped with all the hardware and electronics needed to start growing. There is an integrated reservoir, irrigation pump and controller that can be accessed manually or through a smart phone. Whether you are a beginner or experienced grower – the Harvest Wall Vertigation™ System can suit your needs.

A natural focus of Harvest Today’s sales has been the Canadian Market – where Founder, Rick Langille is from. Canada has no shortage of rural, northern hemisphere regions where fresh produce is simply unavailable. Harvest Today currently has several operating farms in rural communities across Canada. We work with numerous First Nation organizations for not only food production, but also ceremonial herbs and spices no longer available to the indigenous peoples of the area.

The phrase, “It Takes A Village,” always comes to mind when discussing Harvest Today’s partnerships and collaborations. Yes, we build walls, that’s what we do. But Harvest Today isn’t just here to build walls – our objective is to GROW FOOD, and we can’t do it alone. Having solid trusted partners to help round out the offering and provide expertise in their field is our village – whether it’s lighting, cooling, consumables or anything in-between, we want to be able to point our customers in the right direction.

I’d like to call out SpectraGrow here, as our go-to LED lighting partner. Having SpectraGrow as a resource means we can confidently provide our customers with the latest in LED hardware and technology. With so many options out there – it can be daunting for a potential customer to just google “grow lights.” We want to be that resource and having trusted partners is the only way to do it.

A cool thing about this business – for the most part, is that what’s good for ESG, is also usually good for business. It’s not a this or that sort of situation. No matter how or where a Harvest Wall is being used – it’s growing local food – and that’s what we’re here for.

We are very proud ESG efforts and make them a focus of our everyday operations and lives. From an access point of view – when we say we’re here to grow food, we mean it! That’s the number one objective, grow local healthy food. The positive impact of just that, growing local healthy food, knows no bounds.

We will be launching our 4 port grow tile for the Harvest Today Harvest Wall Vertigation™ System. Our standard 6 port grow tile consists of 6 2” plant ports. The 4 port grow tile will have 4 3.25” plant ports. The volume of each port on the 4 port grow tile will be nearly 5x that of the 2” ports. This will provide a significantly larger root zone greatly expanding the portfolio of plants that can be grown in a Harvest Wall – most notably – larger fruiting and vining plants like tomatoes, strawberries, cucumbers, peppers, and more.

We will be launching our 4 port grow tile for the Harvest Today Harvest Wall Vertigation™ System. Our standard 6 port grow tile consists of 6 2” plant ports. The 4 port grow tile will have 4 3.25” plant ports. The volume of each port on the 4 port grow tile will be nearly 5x that of the 2” ports. This will provide a significantly larger root zone greatly expanding the portfolio of plants that can be grown in a Harvest Wall – most notably – larger fruiting and vining plants like tomatoes, strawberries, cucumbers, peppers, and more.

For more information on Harvest Today, visit the website.

Vertical Harvest Farms, an indoor farming company focused on customized employment for people with disabilities, is proud to announce the closing of $59.5 million in project financing to develop and operate a 51,000 square-foot hydroponic vertical farm in downtown Westbrook, Maine.

The project is a critical piece of the state’s food system infrastructure and will significantly contribute to the New England Food Vision, where the region’s six states committed to a goal of locally producing 30 percent of the food consumed in the region by 2030 (and 50 percent of the region’s food by 2060), by producing approximately 2.5 million pounds of fresh, leafy greens every year – ranging from mature lettuce, petite greens, microgreens and herbs.

This project also aligns with Vertical Harvest’s “feed locals first” philosophy and goal of providing greens from farm-to-fridge within 24 hours. In this way, the company helps New Englanders avoid the 30 percent loss of nutritional value that occurs within three days of harvest, which widely affects the produce shipped into the region from California, Arizona and abroad. It also significantly helps mitigate food waste by providing longer shelf life and less shrinkage at the retail and institutional level. The company offers these benefits while fulfilling its dual mission to grow food and futures by offering meaningful employment for people with disabilities in this emerging, tech-forward sector.

Vertical Harvest CEO Nona Yehia said, “We’re on a mission to grow food as local, fresh and fair as possible, and ensure there’s a place at the table for everyone in the future of food.”

As the US became a net food importer for the first time ever in 2023, stakeholders are realizing that traditional agriculture is under greater stress from extreme weather, water scarcity and climate change. This has made diversifying food production, leveraging technologic innovations, shortening supply chains, and ensuring access to fresh local food for years to come, imperative. USDA Rural Development recognizes this as well and is incentivizing efforts to future proof the food system.

“As ‘The People’s Department’ we are happy to support fresh food, and good jobs here in Maine, as well as the equity of access to both. USDA Rural Development is committed to building communities and feeding Mainers, and we look forward to Vertical Harvest being a part of the team fulfilling those shared goals,” said USDA Rural Development Maine State Director, Rhiannon Hampson.

This funding also aligns with the CEA Industry’s shift to project-level financing. Vertical Harvest is excited by the public and private partners that made this deal possible.

“We are thrilled to provide financing and partner with Vertical Harvest. Through two pioneer programs from the USDA and other community facilities, we were able to creatively structure this challenging project. We believe this will have a tremendous impact on the local community and the future of food production,” said Alexios Georgousis, Madison One CUSO.

The funding was led by Madison One and supported by Waterside Commercial Finance. The financing includes $25 million and $23,795,000 loans that utilize USDA Rural Development Business & Industry Loan Guarantees and Rural Energy for America Program (REAP) Renewable Energy and Energy Efficiency Loans, respectively.

This financing is supplemented by a $8,655,189 Commercial Property Assessed Clean Energy (C-PACE) loan – the first in Maine administered by the Efficiency Maine Green

Bank and issued through Nuveen Green Capital – and $2,000,000 of American Rescue Plan (ARPA) funding through the Finance Authority of Maine (FAME).

“We are pleased to have approved Vertical Harvest for this funding through the Efficiency Maine Green Bank in partnership with one of our capital providers, Nuveen Green Capital,” said James Neal, senior manager for finance initiatives at Efficiency Maine. “We strongly encourage more of Maine’s municipalities to follow Westbrook’s example and adopt this ordinance so their local businesses can take advantage of this unique pathway to finance energy improvements, such as upgrading lighting or installing heat pump systems for heating and cooling in their buildings.”

In addition, borrower and partner contributions of $19,189,210 are possible thanks to partners such as Crossroads Impact Corp, Enhanced Capital, Foundation Credit, Waterside Commercial Finance, Maine Technology Institute, and others.

“Public-private partnerships benefit a wider group of stakeholders than private capital can alone,” said Enhanced Capital’s Chief Impact Officer and Managing Director Gingee Prince. “In 2017, we partnered with Vertical Harvest to pioneer this space and are excited to see them building even more ambitious capital coalitions today.”

This array of funding follows Vertical Harvest’s model of using public-private partnerships to catalyze resilience within a state’s food system. The company believes this financing model, piloted in Wyoming and now proven in Maine, will pave the way for financing future farms such as the company’s next facility in Detroit, Michigan to be developed in partnership with Bedrock. By bringing together municipal, state and federal funding alongside private capital, not only is the company relocalizing production of perishable produce closer to consumers, but because of Vertical Harvest’s social mission, delivering outsized impact, inclusively.

About Vertical Harvest

Vertical Harvest is a hydroponic, vertical farming company dedicated to community-oriented farms, food and futures. In addition to their passion for local, healthy food grown sustainably, Vertical Harvest also operates on an inclusive, customized employment model with farms designed for accessibility and staffed via hiring practices developed to support meaningful employment for people with disabilities. For more information visit www.verticalharvestfarms.com and sign up for the newsletter, or https://verticalharvestfarms.com/invest-in-vertical-harvest/ to learn about a community raise or follow on socials at @verticalharvestfarms.

Resource Innovation Institute (RII), a not-for-profit, public-private partnership advancing climate resilience, announced today the availability of its “Guide to Environmental Accounting and Reporting for Controlled Environment Agriculture Operations.” Resulting from the work of the CEA Footprint Project over the past year, the how to guide proposes standardized environmental accounting and reporting systems and methodologies, and encourages their market adoption across CEA operations.

Read more and get free download via the Resource Innovation Institute site here.

“Comparing resource outputs and inputs at a facility level and across agricultural segments is increasingly critical for CEA investors and operators, as well as governments and utilities,” said Derek Smith, Executive Director of Resource Innovation Institute. “Agreement on how resources are measured is particularly important, as is the establishment of boundaries determined within the measurement systems. The sooner data can be standardized, collected and analyzed, the quicker and better decision makers can guide efficiency and decarbonization strategies and incentives.”

“The indoor farming industry has the opportunity to drive consensus on data standardization at this early stage of the industry’s growth through collaborative, well-governed efforts like the CEA Footprint Project,” said Julie Kurnik, Senior Director of Innovation Start Ups at World Wildlife Fund. “RII’s Guide establishes comprehensive CEA-specific guidance on measurement methodologies, importantly including how to establish boundaries on scope 3 carbon emissions. This type of reporting will result in consistent communication on the environmental value and direction that will drive long-term viability for technology integration into agriculture.”

A collaborative initiative by RII, producers and stakeholders, the CEA Footprint Project was formed to advance market understanding of CEA environmental impacts and resilience potential through the establishment of consistent and verifiable accounting and reporting standards. In order to develop the Guide to Environmental & Accounting Reporting, CEA Footprint Project members from the United States and Europe came together in early 2023 to discuss the most important Key Performance Indicators they use and value in their facilities, as well as to agree on which KPIs are relevant to internal and external audiences, in addition to where in the production process CEA operators should measure data. The group also aggregated detailed guidance on how producers should consider representing CEA-related Scope 3 carbon emissions boundaries and methodologies.

Participating producers that contributed to the guide included:

Read more and get free download via the Resource Innovation Institute site here.

New York-based controlled environment agriculture company Square Roots has unveiled a program that aims to remove lighting from commercial indoor vertical farming systems to reduce energy demands and costs.

New York-based controlled environment agriculture company Square Roots has unveiled a program that aims to remove lighting from commercial indoor vertical farming systems to reduce energy demands and costs.

Through partnerships and focused research, the company says it is exploring techniques like heterotrophic growing to operate indoor farms in the dark, with the goal of lower production costs and environmental impact while maintaining year-round fresh food production.

“Over the last 12 months Square Roots has created a platform to accelerate agricultural research, working with partners across both indoor and outdoor farming, alongside science-focused organizations and foundations,” Square Roots co-founder and CEO Tobias Peggs told The Packer.

The program seeks to demonstrate that light can be removed from a commercial indoor vertical farming system; the benefits of indoor farming remain, but the system can now operate with radically reduced energy needs. This translates directly to significantly lower production costs and associated carbon dioxide equivalent, or CO2e, he said.

To enable this new approach, Square Roots is working with gene-edited CRISPR plants that add biomass by uptaking carbon through their root systems rather than relying on photosynthesis under light. The underlying science was initially developed by Robert Jinkerson, a specialist in artificial photosynthesis at the University of California, Riverside, in conjunction with Feng Jiao, a chemist at the University of Delaware.

For greenhouse growers, the siren song of growth and expansion is undeniable. It whispers increased yields, broader markets and greater financial stability. But like any seductive melody, it masks a treacherous undertow. While brimming with potential, challenges lurk unseen, ready to overwhelm with complexities, resource strains and logistical nightmares.

For greenhouse growers, the siren song of growth and expansion is undeniable. It whispers increased yields, broader markets and greater financial stability. But like any seductive melody, it masks a treacherous undertow. While brimming with potential, challenges lurk unseen, ready to overwhelm with complexities, resource strains and logistical nightmares.

A fundamental entrepreneurial principle, especially relevant for greenhouse growers, is that expansion should be a deliberate strategic decision, not solely a reaction to opportunity. This principle rings true for Brooklyn, New York-based Gotham Greens, which has navigated numerous recent expansion projects with calculated precision. Led by the visionary leadership of co-founders Viraj Puri (CEO) and Eric Haley (CFO) and Chief Greenhouse Officer Jenn Frymark and supported by a dedicated internal team of horticulture pros, Gotham Greens carefully examined every expansion challenge and established effective best practices. This has empowered the grower to overcome the complexities of a revolutionary way of growing and providing fresh produce in the U.S.

Today, Gotham Greens is synonymous with urban agriculture and cutting-edge, sustainable growing practices, and its growth and expansion wouldn’t be done justice without highlighting its rapid ascent in the greenhouse grower market.

Today, Gotham Greens is synonymous with urban agriculture and cutting-edge, sustainable growing practices, and its growth and expansion wouldn’t be done justice without highlighting its rapid ascent in the greenhouse grower market.

Its legacy is rooted in the heart of Brooklyn, New York, an urban, culturally diverse foodie paradise. In 2009, Puri and Haley collaborated on a shared dream to provide fresh, pesticide-free, sustainably grown produce directly to local communities. Two years later, the vision materialized on a Greenpoint neighborhood rooftop with Gotham Greens’ first 15,000-square-foot soilless hydroponic greenhouse, marking a milestone in traditional farming. At its heart, this revolutionary model addressed long-held agricultural challenges — how to overcome long distances, mitigate environmental impact and provide greater access to fresh, locally produced foods.

The Controlled Environment Agriculture (CEA) Summit East returns to the Institute for Advanced Learning and Research (IALR) Conference Center in Danville, Virginia from October 1-2, 2024. Co-hosted by Indoor Ag-Con, the leading trade show and conference for the vertical farming | greenhouse | CEA sector, and the Virginia Tech (VT)-IALR CEA Innovation Center, a joint project of the IALR and Virginia Tech’s School of Plant and Environmental Sciences and Virginia Seafood Agricultural Research and Extension Center, the summit continues to serve as a premier platform for industry collaboration and innovation.

Building on the success of its 2023 edition, which attracted attendees from 33 US states, Canada, the Netherlands and Sweden, the 3rd Annual CEA Summit East is set to unite professionals once again from academia, business, and technology within the CEA industry. Attendees include greenhouse growers, urban agriculture operations, vertical farms, outdoor growers seeking hybrid growing opportunities, educators, scientists, Virginia Cooperative Extension personnel, suppliers, engineers, tech specialists, architects/developers, government officials, and other industry members.

“Our partnership with the VT-IALR CEA Innovation Center underscores our commitment to fostering an environment where industry leaders and academia come together to drive innovation and explore new opportunities within the CEA sector,” says Brian Sullivan, CEO, Indoor Ag-Con.

With a focus on facilitating meaningful connections and knowledge exchange, the summit will feature keynote presentations, panel discussions, networking/breakout sessions, and tabletop exhibits highlighting the latest advancements in CEA technology and practices. Attendees can also look forward to research facility tours, providing firsthand insights into cutting-edge research and development initiatives.

“The CEA Summit serves as a platform for showcasing the collaborative efforts between industry and academia in advancing CEA research and education,” adds Dr. Scott Lowman, Co-Director of the VT-IALR CEA Innovation Center and Vice President of Applied Research at IALR. “We are eager to continue driving the momentum of the CEA industry and providing attendees with valuable opportunities for learning, networking, and growth.”

For more information on the 3rd Annual CEA Summit East, including registration, speaking and exhibit opportunities, visit the event website at www.ceasummit.com.

Founded in 2013, Indoor Ag-Con has emerged as the largest trade show and conference for vertical farming | greenhouse |controlled environment agriculture. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis | hemp, alternate protein and non-food crops. More information, visit www.indoor.ag.

The Virginia Tech-IALR Controlled Environment Agriculture Innovation Center is a joint project between IALR and Virginia Tech’s School of Plant and Environmental Sciences and the Virginia Seafood Agricultural Research and Extension Center. By developing strategic partnerships with both industry and academia, the goal of the Innovation Center is to conduct research and educational programming to develop, promote and advance the CEA sector in the U.S. and internationally. More information – www.ialr.org/cea

Amsterdam and Indoor Ag-Con, Las Vegas, NV – March 11, 2024 – Skytree, a pioneering climate tech company specializing in carbon utilization and removal solutions, today announced the availability of Skytree Stratus, the company’s newest decentralized Direct Air Capture (DAC) unit for onsite carbon capture and utilization. The Skytree Stratus unit can generate as much as 2750 lbs. (1250kg) of CO2 per day to meet the needs of large greenhouses and vertical farms.

Stratus is Skytree’s second decentralized DAC unit brought to market in the last seven months, following the launch of the smaller scale Skytree Cumulus launched last fall. Cumulus units are currently generating CO2 at CEA facilities around the world including Wageningen University & Research Center in The Netherlands.

Once installed onsite, Stratus captures CO2 from the ambient air to be deployed to enrich crop yield and increase productivity. The fully modular nature of Stratus allows for multiple units to be combined into a “Skytree Stratus Hub” to meet larger volume needs. Through partnerships, Skytree offers local liquefaction of CO2, required for storage of liquid CO2, enabling CEA businesses to continuously capture and store CO2 in use during peak production periods.

Once installed onsite, Stratus captures CO2 from the ambient air to be deployed to enrich crop yield and increase productivity. The fully modular nature of Stratus allows for multiple units to be combined into a “Skytree Stratus Hub” to meet larger volume needs. Through partnerships, Skytree offers local liquefaction of CO2, required for storage of liquid CO2, enabling CEA businesses to continuously capture and store CO2 in use during peak production periods.

Stratus is available in hybrid and all-electric-powered configurations, designed to optimally integrate with the location’s onsite energy source. The dual-powered Skytree Stratus Hybrid uses onsite thermal heat which reduces the need for electricity, delivering considerable savings as compared to the all-electric version. Over time, Skytree expects to drive Stratus’ energy consumption to under 1kWh per kg of CO2 generated.

“Following the successful commercial launch of the Skytree Cumulus, we are excited to debut our much larger Stratus system with shipments starting later this year,” said Rob van Straten, Skytree CEO. “The introduction of Stratus reflects our great momentum and the strides we continue to make in providing CEA businesses with an innovative alternative to fossil fuel-based CO2. CEA businesses facing or expecting supply chain challenges and price instability want an independent and continuous supply of CO2,” van Straten continued. “Stratus offers a reliable CO2 source for businesses seeking to boost crop yield while, at the same time, securing supply, and reducing carbon footprint.”

Through the company’s Uptime Assurance Guarantee program, Skytree guarantees high uptime, monitors, and measures CO2 generation, and conducts all preventive and corrective maintenance to ensure uninterrupted operations.

For more information about Skytree Stratus, click here:

About Skytree:

Founded in 2014 and headquartered in Amsterdam, Skytree harnesses CO2 from ambient air through the power of direct air capture technology (DAC). By providing local, onsite CO2 generation across multiple markets including vertical farming, greenhouses as well as mineralization, Skytree enables a transition away from fossil fuel-based industrial processes and avoids transport to where the CO2 is needed.

Born out of the European Space Agency (ESA), during the development of a CO2 scrubber, space scientists evaluated over 50 sorbents. Skytree founder, Max Beaumont, was a system engineer on this team and spun out the technology through the ESA incubator program ‘ESA-BIC’. With a decade of research & development, the company has since registered 17 patents, in 5 patent families across US, Europe, and China and is ready to monetize the technology through multiple use cases.

The Skytree Stratus initially is focused on high tech greenhouses that require large volumes of CO2 with initial customers in The Netherlands, Canada and United States.

(Raleigh, North Carolina – March 11, 2024) AGEYE, a forefront innovator in AI-powered crop intelligence for controlled environment agriculture (CEA), proudly announces its strategic acquisition of the HYVE® brand from DASCOM Americas. The company will also assume leadership roles for sales, installation, and support of HYVE systems moving forward. This pivotal move, an extension of the partnership that started in 2022, merges AGEYE’s leading AI technology with HYVE’s scalable, automated vertical farming system, and provides a clear and focused team and direction that will bring undistracted attention in providing the best, most comprehensive system for commercial farming operations.

Nick Genty, CEO of AGEYE, highlighted the industry’s challenges: “Vertical farmers often struggle with piecing together disparate solutions from various providers, leading to inconsistent results. Some have attempted to develop their own technologies, usually facing limited success and budget overruns. We’ve taken a fundamentally unique approach, combining task-specific yet straightforward technologies to provide a comprehensive, superior alternative that has already demonstrated success in the market.”

Central to this innovative solution is the automation of the entire plant lifecycle, from seeding to harvest. Efficient and practical robotics technology significantly reduces human errors, improves plant health, and lowers labor costs, all without the substantial financial investment typically required by advanced technologies. Enhanced by AGEYE’s sophisticated analytics and crop monitoring, this automation supports informed, data-driven decisions across all farming operations – from irrigation and nutrition to lighting, climate control, and harvesting, setting a new standard for the industry. The comprehensive solution is designed to address the real-world challenges faced by vertical farmers, aiding in lowering operational expenses and growing cost-competitive crops.

“The acquisition of the HYVE brand and day-to-day leadership underscores our commitment to advancing indoor agriculture through technology,” said Bashir Jabbour, Senior Director of Product at AGEYE. “Our turnkey solution, where every component is precisely designed to work together, simplifies the journey to success for growers in a competetive landscape. This cohesive approach allows growers to focus on their primary skill: growing. It spares them the complexity of managing multiple vendors and accelerates the operational setup.”

According to Ron Acorn, President of DASCOM Americas: “AGEYE and HYVE have worked together in a strategic capacity over the course of the last several years. Nick is a seasoned leader, full of energy, and very focused with a

team that is well positioned to take HYVE to a new level. This deal comes at a very opportune time for both companies. AGEYE is geographically and strategically well-positioned to maximize the capabilities of a more full- scale integration of the specific abilities of both companies. The combination of the system infrastructure we have cultivated to this point combined with their superior technology leadership means that there is now one source with a fully focused vision to give commercial growers the most viable and comprehensive pathway to success in their indoor farming pursuits. It is both strategic and practical for AGEYE to assume a more prominent role in bringing this comprehensive solution to market. AGEYE’s leadership, technical expertise, and depth of experience add the final missing piece to an unmatched recipe for prospective indoor farmers who will without doubt change the landscape of commercial farming moving forward.”

This move marks a significant step in AGEYE’s effort to transform vertical farming into a well-known, dependable, and financially viable way to grow crops all year, moving it from a niche method to a widely accepted, sustainable form of agriculture. The goal is to make advanced crop intelligence and automation technology accessible to indoor farmers of all sizes, enhancing their productivity and ensuring sustainable and continuing operations.

For More Information:

To learn more about our solutions and technologies, please visit our websites: AGEYE Technologies: https://ageyetech.com

Grow HYVE: https://growhyve.com

Follow us on social media for the latest updates and insights: Instagram: @ageyetech

LinkedIn: AGEYE Technologies and HYVE Indoor Farming

About AGEYE:

AGEYE specializes in advanced farm management software, IoT devices, AI-driven crop analytics, and fully automated robotic solutions for vertical farming. Our focus is on enhancing revenue per square foot using data- driven precision agriculture. We’re dedicated to making indoor farming viable and profitable by embracing sustainability and leveraging intelligence to simplify complexities. Our technology empowers indoor growers to transform challenges into opportunities, setting new standards for the future of controlled environment agriculture.

About HYVE:

HYVE is a business unit of DASCOM Americas which serves the Americas markets and is wholly owned by DASCOM Holdings, a Hong Kong-based company with more than 30 years of experience in providing technology solutions. The company does business in more than eighty countries around the globe and offers diverse solutions for customers in a broad range of markets.

In a groundbreaking debut at Indoor Ag-Con, Sollum Technologies, the leader in dynamic LED grow light solution, announces its commitment to go beyond revolutionizing indoor agriculture to make a significant impact on the local community by partnering with Three Square, Southern Nevada’s only food bank.

In a groundbreaking debut at Indoor Ag-Con, Sollum Technologies, the leader in dynamic LED grow light solution, announces its commitment to go beyond revolutionizing indoor agriculture to make a significant impact on the local community by partnering with Three Square, Southern Nevada’s only food bank.

For each demo of its innovative SUN as a Service® platform performed during the event, Sollum® pledged to donate $ 100 USD directly to Three Square. On the second day of the show, Sollum donated $ 3,000 USD, which will contribute to serving approximately 9,000 meals.

Sollum Technologies designed the only 100% dynamic LED lighting solution that modulates the full spectrum of the Sun’s natural light to illuminate closed environments such as greenhouses, research centers and laboratories. Sollum’s award-winning, turnkey solution consists of internet of things, AI-powered light fixtures that are controlled by Sollum’s proprietary SUN as a Service® cloud platform.

Sollum Technologies designed the only 100% dynamic LED lighting solution that modulates the full spectrum of the Sun’s natural light to illuminate closed environments such as greenhouses, research centers and laboratories. Sollum’s award-winning, turnkey solution consists of internet of things, AI-powered light fixtures that are controlled by Sollum’s proprietary SUN as a Service® cloud platform.

Sollum’s distinctive proposition is a fully scalable cleantech solution that evolves with business needs and multi-zone light management, with each zone benefiting from automatic dimming of an unlimited number of light recipes; this is why it provides unparalleled value in terms of energy savings and, additionally for greenhouse growers, increased productivity and superior produce quality.

ABOUT SOLLUM

Founded in 2015, the company is headquartered in Montréal (Québec, Canada), where its design, development, and manufacturing activities are concentrated, and has a representative office in Leamington (Ontario, Canada). For more information, visit sollum.tech.