AGEYE Announces Aquisition of HYVE Brand At Indoor Ag-Con

AGEYE will Assume Sales, Installation, and Support of HYVE Systems Moving Forward

(Raleigh, North Carolina – March 11, 2024) AGEYE, a forefront innovator in AI-powered crop intelligence for controlled environment agriculture (CEA), proudly announces its strategic acquisition of the HYVE® brand from DASCOM Americas. The company will also assume leadership roles for sales, installation, and support of HYVE systems moving forward. This pivotal move, an extension of the partnership that started in 2022, merges AGEYE’s leading AI technology with HYVE’s scalable, automated vertical farming system, and provides a clear and focused team and direction that will bring undistracted attention in providing the best, most comprehensive system for commercial farming operations.

Nick Genty, CEO of AGEYE, highlighted the industry’s challenges: “Vertical farmers often struggle with piecing together disparate solutions from various providers, leading to inconsistent results. Some have attempted to develop their own technologies, usually facing limited success and budget overruns. We’ve taken a fundamentally unique approach, combining task-specific yet straightforward technologies to provide a comprehensive, superior alternative that has already demonstrated success in the market.”

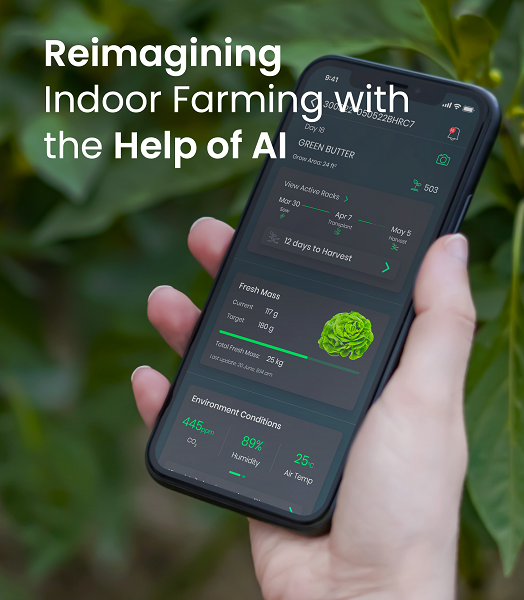

Central to this innovative solution is the automation of the entire plant lifecycle, from seeding to harvest. Efficient and practical robotics technology significantly reduces human errors, improves plant health, and lowers labor costs, all without the substantial financial investment typically required by advanced technologies. Enhanced by AGEYE’s sophisticated analytics and crop monitoring, this automation supports informed, data-driven decisions across all farming operations – from irrigation and nutrition to lighting, climate control, and harvesting, setting a new standard for the industry. The comprehensive solution is designed to address the real-world challenges faced by vertical farmers, aiding in lowering operational expenses and growing cost-competitive crops.

“The acquisition of the HYVE brand and day-to-day leadership underscores our commitment to advancing indoor agriculture through technology,” said Bashir Jabbour, Senior Director of Product at AGEYE. “Our turnkey solution, where every component is precisely designed to work together, simplifies the journey to success for growers in a competetive landscape. This cohesive approach allows growers to focus on their primary skill: growing. It spares them the complexity of managing multiple vendors and accelerates the operational setup.”

According to Ron Acorn, President of DASCOM Americas: “AGEYE and HYVE have worked together in a strategic capacity over the course of the last several years. Nick is a seasoned leader, full of energy, and very focused with a

team that is well positioned to take HYVE to a new level. This deal comes at a very opportune time for both companies. AGEYE is geographically and strategically well-positioned to maximize the capabilities of a more full- scale integration of the specific abilities of both companies. The combination of the system infrastructure we have cultivated to this point combined with their superior technology leadership means that there is now one source with a fully focused vision to give commercial growers the most viable and comprehensive pathway to success in their indoor farming pursuits. It is both strategic and practical for AGEYE to assume a more prominent role in bringing this comprehensive solution to market. AGEYE’s leadership, technical expertise, and depth of experience add the final missing piece to an unmatched recipe for prospective indoor farmers who will without doubt change the landscape of commercial farming moving forward.”

This move marks a significant step in AGEYE’s effort to transform vertical farming into a well-known, dependable, and financially viable way to grow crops all year, moving it from a niche method to a widely accepted, sustainable form of agriculture. The goal is to make advanced crop intelligence and automation technology accessible to indoor farmers of all sizes, enhancing their productivity and ensuring sustainable and continuing operations.

For More Information:

To learn more about our solutions and technologies, please visit our websites: AGEYE Technologies: https://ageyetech.com

Grow HYVE: https://growhyve.com

Follow us on social media for the latest updates and insights: Instagram: @ageyetech

LinkedIn: AGEYE Technologies and HYVE Indoor Farming

About AGEYE:

AGEYE specializes in advanced farm management software, IoT devices, AI-driven crop analytics, and fully automated robotic solutions for vertical farming. Our focus is on enhancing revenue per square foot using data- driven precision agriculture. We’re dedicated to making indoor farming viable and profitable by embracing sustainability and leveraging intelligence to simplify complexities. Our technology empowers indoor growers to transform challenges into opportunities, setting new standards for the future of controlled environment agriculture.

About HYVE:

HYVE is a business unit of DASCOM Americas which serves the Americas markets and is wholly owned by DASCOM Holdings, a Hong Kong-based company with more than 30 years of experience in providing technology solutions. The company does business in more than eighty countries around the globe and offers diverse solutions for customers in a broad range of markets.

In a groundbreaking debut at

In a groundbreaking debut at  Sollum Technologies designed the only 100% dynamic LED lighting solution that modulates the full spectrum of the Sun’s natural light to illuminate closed environments such as greenhouses, research centers and laboratories. Sollum’s award-winning, turnkey solution consists of internet of things, AI-powered light fixtures that are controlled by Sollum’s proprietary SUN as a Service® cloud platform.

Sollum Technologies designed the only 100% dynamic LED lighting solution that modulates the full spectrum of the Sun’s natural light to illuminate closed environments such as greenhouses, research centers and laboratories. Sollum’s award-winning, turnkey solution consists of internet of things, AI-powered light fixtures that are controlled by Sollum’s proprietary SUN as a Service® cloud platform.

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised.

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised. AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable.

AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable. There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

Headquartered in Pittsburgh, Fifth Season’s newest vertical farm in Braddock, PA, a historic steel town on the edge of Pittsburgh, features a 25,000-square-foot grow room with twice the growing capacity of traditional vertical farms. It is set to grow more than 500,000 lbs. of produce in its first full year of operation.

Headquartered in Pittsburgh, Fifth Season’s newest vertical farm in Braddock, PA, a historic steel town on the edge of Pittsburgh, features a 25,000-square-foot grow room with twice the growing capacity of traditional vertical farms. It is set to grow more than 500,000 lbs. of produce in its first full year of operation.

Not at all. We are extremely differentiated in this space given our technology and economics. Furthermore, the real competition is traditional outdoor growing out West. Our industry needs to adopt scalable technologies faster, if we’re going to win. At Fifth Season, we’ve developed the first truly scalable technology platform with positive unit economics that work today with one facility – not 5 years from now with a requirement of 5+ facilities. This is also an industry-first.

Not at all. We are extremely differentiated in this space given our technology and economics. Furthermore, the real competition is traditional outdoor growing out West. Our industry needs to adopt scalable technologies faster, if we’re going to win. At Fifth Season, we’ve developed the first truly scalable technology platform with positive unit economics that work today with one facility – not 5 years from now with a requirement of 5+ facilities. This is also an industry-first.

To-date, Indoor Ag has unfortunately been held back by overhyped, false promises and facade tech demonstrations. It’s time to put that behind us and finally usher in the Indoor Ag future we’ve all been waiting for – with Fifth Season technology.

To-date, Indoor Ag has unfortunately been held back by overhyped, false promises and facade tech demonstrations. It’s time to put that behind us and finally usher in the Indoor Ag future we’ve all been waiting for – with Fifth Season technology. Adam Greenberg

Adam Greenberg with, it’s easy for things to fall through the cracks. Forecasting presents an even bigger challenge that oftentimes ends up as a combination of best guesses and constant fine-tuning. During planning, issuing a single change order can take up to a week as the team works though that excel document. We aim to solve all these challenges with the clarity that comes from a quantifiable, data-driven process that takes the guesswork out of growing.

with, it’s easy for things to fall through the cracks. Forecasting presents an even bigger challenge that oftentimes ends up as a combination of best guesses and constant fine-tuning. During planning, issuing a single change order can take up to a week as the team works though that excel document. We aim to solve all these challenges with the clarity that comes from a quantifiable, data-driven process that takes the guesswork out of growing. LUNA is a SaaS model where clients make recurring payments. As the camera vision captures images while riding around the greenhouse/indoor farm, it sends those images to LUNA’s data collection point where it is translated onto an app the grower can access on a cellphone or laptop. There are multiple pixels per millimeter and each photo and every single pixel is collected and analyzed. That leads to recurring costs and ongoing analysis. The more passes the camera makes, the costs are adjusted accordingly. Each customer — and each order iUNU gets from these customers — is unique. The iUNU team essentially acts as a semi-autonomous horticultural consultant as we recommend the number of passes needed to meet a grower’s goals and needs. This can range from a single daily pass for a grower seeking to find problems with chlorosis or mildew up to 8-10 passes a day for that grower who is a voracious consumer of data.

LUNA is a SaaS model where clients make recurring payments. As the camera vision captures images while riding around the greenhouse/indoor farm, it sends those images to LUNA’s data collection point where it is translated onto an app the grower can access on a cellphone or laptop. There are multiple pixels per millimeter and each photo and every single pixel is collected and analyzed. That leads to recurring costs and ongoing analysis. The more passes the camera makes, the costs are adjusted accordingly. Each customer — and each order iUNU gets from these customers — is unique. The iUNU team essentially acts as a semi-autonomous horticultural consultant as we recommend the number of passes needed to meet a grower’s goals and needs. This can range from a single daily pass for a grower seeking to find problems with chlorosis or mildew up to 8-10 passes a day for that grower who is a voracious consumer of data.