DANVILLE, VA (SEPTEMBER 19, 2022) – AeroFarms Chief Technology Officer Roger Buelow will lead the opening morning keynote address for the inaugural edition of the CEA Summit East, October 25-26, 2022. Indoor Ag-Con and the Controlled Environment Agriculture (CEA) Innovation Center –– a joint project of the School of Plant and Environmental Sciences at Virginia Tech, Virginia Seafood Agricultural Research and Extension Center at Virginia Tech, and the Institute for Advanced Learning and Research (IALR) – have partnered to co-host the new event at the IALR Institute Conference Center in Danville, VA.

This announcement follows on the heels of the grand opening of AeroFarms Danville, the world’s largest aeroponic smart farm, capable of growing more than 3 million pounds of fresh leafy greens annually to meet increased consumer demand.

During his address on Tuesday morning, October 25, 2022 at 8:45 am, Buelow will share more about the new Danville farm and how it utilizes AeroFarms proprietary indoor vertical farming technology to grow more plants at the highest productivity per square foot with the least amount of natural resources – continuing AeroFarms legacy of continuous improvement and innovation. In addition to the environmental benefits, Buelow will discuss benefits the farm brings to the Southern Virginia region ranging from job creation and year-round access to safe, fresh greens to hands-free farming with end-to-end automation from seeding to growing to harvest to packing.

In addition, he will also share updates on some of the exciting plant research and workforce development projects he and his team are working on with Virginia Tech, the IALR and the CEA Innovation Center.

As CTO, Roger Buelow leads the innovation and capabilities team for AeroFarms and works closely with R&D and Business Development. He is an LED innovator and engineering technologist with over 20 years of experience in government and the private sector. Roger previously served as CTO of Energy Focus (a publicly traded company) for ten years leading their R&D, Engineering, and Operations to refit the U.S. Navy with LEDs, develop lights that leverage blue light to help regulate sleep cycles, and to set the world’s record for most efficient solar cell.

Roger worked with AeroFarms in 2009 to help with lamp and fixture design, and he brings his extensive network and industry expertise with LEDs. He has been the principal investigator on over a dozen federally funded research contracts spanning military and civilian technologies and holds over 20 patents covering a wide array of technologies. Roger has brought over 50 products from concept, through R&D, into engineering, and then onto the open market. Roger has a B.S. in Mathematics and an M.S. in Systems and Control Engineering from Case Western Reserve University, Cleveland, Ohio.

Learn more about this exciting keynote session and the full conference program here.

“Roger Buelow’s extensive experience and keen industry insights, coupled with the AeroFarms Danville-Pittsylvania story, come together to create the perfect program to kick off the new CEA Summit,” says Dr. Michael Evans, Director of the School of Plant and Environmental Sciences at Virginia Tech and Associate Director of the CEA Innovation Center. “We are thrilled to have Roger join the keynote stage and know our audience will be eager to hear from him.”

The new CEA Summit East is custom-tailored for new and well-seasoned CEA industry members from throughout the Eastern US, including indoor and greenhouse growers, facility owners and operators, educators, government officials, real estate developers, architects, construction specialists, sales and marketing teams and others.

During the one and one-half day event, industry members will have the opportunity to attend the conference featuring CEA thought leaders, researchers and experts leading keynotes, panels, and breakout sessions; explore tabletop exhibits presenting the latest CEA innovations and services; and enjoy a host of networking opportunities ranging from meals and coffee breaks to an evening social event.

Registration is now open for the event and attendees can save with discounted Early Bird rates when they register before October 7, 2022. Learn more at www.ceasummit.com

QUICK FACTS:

WHEN: Tuesday, October 25 – Wednesday, October 26, 2022

WHERE: IALR Institute Conference Center, 150 Slayton Ave, Danville, VA 24540

INFO: For information on exhibiting or attending visit www.ceasummit.com

ABOUT INDOOR AG-CON

Founded in 2013, Indoor Ag-Con has emerged as the premier trade event for indoor | vertical farming | controlled environment agriculture, the practice of growing crops in indoor systems, using hydroponic, aquaponic and aeroponic techniques. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis |hemp, alternate protein and non-food crops. More information – www.indoor.ag | 404.991.5186

ABOUT THE SCHOOL OF PLANT AND ENVIRONMENTAL SCIENCES AT VIRGINIA TECH

The School of Plant and Environmental Sciences at Virginia Tech trains the next generation of professionals in the fields of plant breeding and genetics, agronomic and horticultural crop production, plant protection, soil and water systems management, agricultural technologies, environmental restoration and agro-environmental stewardship. It conducts research to improve agricultural productivity, reduce negative impacts on the environment and improve soil and water health. Through extension programs, it provides science-based information to stakeholders to help them feed the world while protecting the environment. More information —www.spes.vt.edu

ABOUT THE VIRGINIA SEAFOOD AGRICULTURAL RESEARCH AND EXTENSION CENTER AT VIRGINIA TECH

The Virginia Seafood Agricultural Research and Extension Center at Virginia Tech works to support the future of the historic seafood industry — in Virginia and beyond. Its extension specialists work with industry and research partners to identify and respond to emerging needs and provide technical guidance to stakeholders in every level of the seafood supply chain. Through technical assistance, training, process validation, value-added product development, and more, it helps stakeholders ensure product quality, safety, and viability. More information — www.arec.vaes.vt.edu

ABOUT IALR

The Institute for Advanced Learning and Research (IALR) serves as a regional catalyst for economic transformation. Core focus areas include research that provides a clear path to commercialization, advanced learning opportunities where education meets experience, training and rapid-launch space for advanced manufacturers, and economic development through conferencing and a partnership with the Southern Virginia Regional Alliance. It is located in scenic and historic Danville-Pittsylvania County on the VA/NC state line, within a short drive of Roanoke, Greensboro and Raleigh. More information – www.ialr.org

ABOUT AEROFARMS

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation with global headquarters in Newark, New Jersey. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions in Food, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides ever versus traditional field farming. AeroFarms enables local production to safely grow all year round, using vertical farming for elevated flavor.™ Its products can be found at major selling partners like Ahold Delhaize, Amazon Fresh, Baldor Specialty Food, Compass Group, Harris Teeter, Marcus BP, Momofuku Noodle Bars, ShopRite, The Fresh Market, Walmart, and Whole Foods Market. In addition, through its proprietary growing technology platform, AeroFarms has grown over 550 varieties of plants and has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. More information – www.aerofarms.com

###

Harnessing the power of existing genetics and strategic collaborations,

Harnessing the power of existing genetics and strategic collaborations,  Tell us about the main goals and objectives of Sakata Seed’s CEA division? How does it support the needs and demands of greenhouse grower, vertical farm operators and other indoor growers in the sector?

Tell us about the main goals and objectives of Sakata Seed’s CEA division? How does it support the needs and demands of greenhouse grower, vertical farm operators and other indoor growers in the sector? Could you provide a couple of examples of Sakata Seed’s varieties that have shown exceptional performance in indoor growing environments, and what attributes make them well-suited for CEA?

Could you provide a couple of examples of Sakata Seed’s varieties that have shown exceptional performance in indoor growing environments, and what attributes make them well-suited for CEA? Share some insights into the unique challenges and opportunities that CEA presents for seed development and production, compared to traditional outdoor farming?

Share some insights into the unique challenges and opportunities that CEA presents for seed development and production, compared to traditional outdoor farming? How do you identify and prioritize the traits and characteristics that are more important for indoor growers — are you able to collaborate with growers to gather feedback and insights?

How do you identify and prioritize the traits and characteristics that are more important for indoor growers — are you able to collaborate with growers to gather feedback and insights? Can you highlight any recent advancements or innovations in seed development within your CEA division? What varieties or technologies can growers anticipate from Sakata Seed in the near future.

Can you highlight any recent advancements or innovations in seed development within your CEA division? What varieties or technologies can growers anticipate from Sakata Seed in the near future.

One of Winter Farm’s goals is to help growers replace 10% of Canada’s strawberry imports. Can you speak to some of the environmental and economic benefits that could come from achieving this goal, and how Winter Farm is working to make it a reality?

One of Winter Farm’s goals is to help growers replace 10% of Canada’s strawberry imports. Can you speak to some of the environmental and economic benefits that could come from achieving this goal, and how Winter Farm is working to make it a reality?

What do you see as the biggest opportunities for the CEA industry as a whole in years to come, and how is Winter Farm working to seize them?

What do you see as the biggest opportunities for the CEA industry as a whole in years to come, and how is Winter Farm working to seize them?

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised.

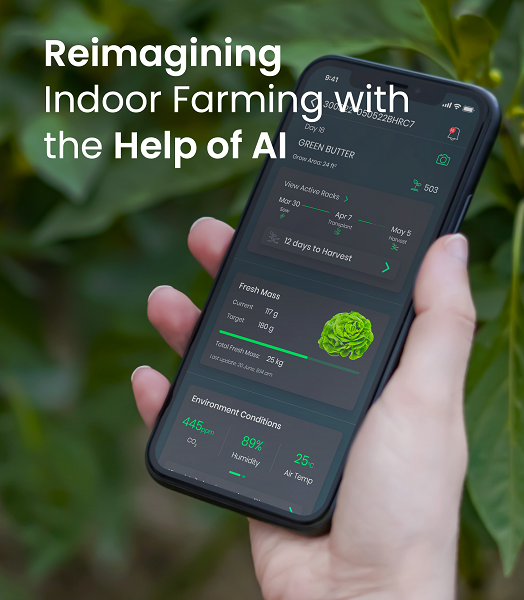

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised. AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable.

AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable. There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.