Talking Automation, Sustainability and Scale With Better Future Farms Co-Founder John McMahon

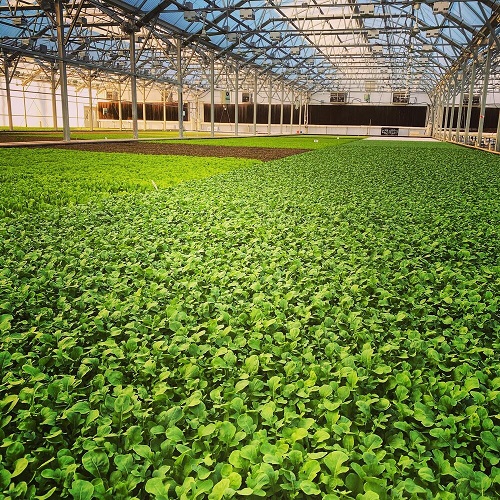

Earlier this month, Virginia Governor Glenn Youngkin announced that Better Future Farms, Inc. will build a new hydroponic greenhouse and processing facility on a 61-acre site in the Louisa County Industrial Air Park. Backed by funding from Generate Capital, a sustainable infrastructure investment and operating platform and a distribution partnership with Taylor Farms, a leading North American producer of salads and healthy fresh foods, the facility is set to come online in 2024. In this month’s CEA Q&A, John McMahon, co-founder/chief operating officer of Better Future Farms and founder of Schuyler Greens, shared insights on their decision to locate in central Virginia’s Louisa County , their sustainability initiatives and long term goals for the company.

What led to the decision to build the new greenhouse and processing facility in Louisa County? What factors made this location the best choice for Better Future Farms?

The decision was driven by both the site and infrastructure. My business partner David Drescher and I both live in the Charlottesville area, and Louisa County is the next county over. In central Virginia it’s hard to find the flat terrain needed for a greenhouse facility. This site had that and the right infrastructure in place in terms of electrical capabilities, natural gas, and proximity to large freeways and distribution logistics.

The decision was driven by both the site and infrastructure. My business partner David Drescher and I both live in the Charlottesville area, and Louisa County is the next county over. In central Virginia it’s hard to find the flat terrain needed for a greenhouse facility. This site had that and the right infrastructure in place in terms of electrical capabilities, natural gas, and proximity to large freeways and distribution logistics.

The local support was another key factor. We looked at several different counties and once we talked to Louisa County about the project and what it entailed, they were incredibly supportive and became great partners throughout the process.

We also wanted to build our first project in our own backyard in Virginia, as we’re from the area and didn’t want to be on a plane every week. Leveraging our existing relationships in the CEA industry in Virginia also played a role. The state is very enthusiastic about the future of CEA and government agencies and organizations like the Virginia Department of Agriculture and Consumer Services and the Virginia Economic Development Partnership were very supportive and helpful. And, of course, Virginia itself is a great choice since it puts the facility within a day’s drive of a large population base.

What will differentiate Better Future Farms from other greenhouse/indoor operations?

I’ve been a grower for about 10 years now, so I tend to be a bit cynical when it comes to making big claims. I would say that we’re investing a significant portion of our capital in automation – in the greenhouse, pack line, and growing system. This decision was influenced by owning and operating a smaller greenhouse for years and recognizing the repetitive tasks that are present in greenhouse operations. The goal of automation is not to replace employees, but to automate the tasks that are repetitive and do not add value, freeing up employees to perform more important tasks.

I see automation is a tool in our toolbox. We’re not a technology company. At the end of the day, our job is to be a sustainable business that grows lettuce at the right price. The focus of the investment and all our innovations is to do that as efficiently as possible.

Can you share more about your partnership with Taylor Farms? How will this collaboration help you reach more customers?

Taylor Farms is one of the largest salad and fresh cut vegetable processors in the world and all our lettuce will be marketed under Taylor Farms’ Earthbound Farms brand. David and I have both been at this for a long time and we know what it takes to build a brand. So, we wanted to team up with an existing brand rather than build a new one from scratch. We talked to several companies and when we met with Taylor Farms, our objectives, philosophies, and values all aligned.

Taylor Farms is one of the largest salad and fresh cut vegetable processors in the world and all our lettuce will be marketed under Taylor Farms’ Earthbound Farms brand. David and I have both been at this for a long time and we know what it takes to build a brand. So, we wanted to team up with an existing brand rather than build a new one from scratch. We talked to several companies and when we met with Taylor Farms, our objectives, philosophies, and values all aligned.

I’m not the type of greenhouse grower seeking to displace field growers. The way the industry is now, greenhouse/controlled environment agriculture production is miniscule compared to what the large California farms put out. But these western growers see a need to diversify the supply chain. Retailers are asking for it because of food safety issues. And, together with post pandemic freight, shipping and other supply chain , water, and weather challenges, it’s gotten more complicated –and more expensive. Greenhouses/CEA can help diversify the supply chain by allowing these large players to grow product closer to the end user.

We have a great relationship with Taylor Farms and are so excited to be working with them. For me, starting as a smaller, niche grower, it’s a huge honor to be growing for the largest lettuce producer.

Can you speak to any specific sustainability initiatives or practices that Better Future Farms will implement in its operations and how they align with Generate Capital’s focus on sustainable agriculture?

Generate Capital is a leading ESG public benefit corporation focused heavily on building and financing solutions for clean energy, water, waste, agriculture and more. They’d been looking at the CEA sector for some time. While we are their first investment here, I expect they will be very active in this space, and not just with us.

Generate Capital is a leading ESG public benefit corporation focused heavily on building and financing solutions for clean energy, water, waste, agriculture and more. They’d been looking at the CEA sector for some time. While we are their first investment here, I expect they will be very active in this space, and not just with us.

We certainly share their focus on sustainable agriculture and have several sustainability initiatives in our operations.

We are harvesting all our rainwater. Virginia consistently gets 44 inches of rain distributed throughout the year. We expect that 90-95% of our irrigation will be reclaimed water. As part of our 14.5-acre facility, we have a 2-acre retention pond that can hold 2.5 million gallons that we’ll be pulling into the greenhouse and using for irrigation.

We’ll also be using 100% LED lights, so there will be no high-pressure sodium lighting and less energy use.

And we’ll always be on the lookout for even more ways to use the least amount of inputs and energy to be as sustainable as possible.

What are your long-term goals for Better Future Farms? What do you hope to achieve in the next few years?

Our goals are to build out multiple facilities in Virginia and other geographical locations, add different products, and grow our partnership with Taylor Farms.

In terms of crops, we’d like to offer different types of lettuce and, possibly, berries. We want to become a diversified producer. The challenge is you need to marry products that complement each other. For example, lettuce and strawberries work well together because they both travel in the cold chain. Tomatoes and vine crops need to be on a warmer truck.

What’s next for Schuyler Greens? Will you still be involved?

I wouldn’t be doing this new project without the knowledge and experience I gained from launching and building Schuyler Greens. I’ve owned Schuyler Greens for more than 9 years now and it encompasses 225 acres outside of Charlottesville with a greenhouse in the middle. I will be keeping Schuyler Greens separate from Better Future Farms.

I wouldn’t be doing this new project without the knowledge and experience I gained from launching and building Schuyler Greens. I’ve owned Schuyler Greens for more than 9 years now and it encompasses 225 acres outside of Charlottesville with a greenhouse in the middle. I will be keeping Schuyler Greens separate from Better Future Farms.

Schuyler Greens is better off as a traditional farm with a greenhouse on it as we don’t have access to the infrastructure or flat terrain needed to scale up a large greenhouse. The value for me is that Schuyler Greens is a true working farm with cattle, timber and other resources.

We really live in an Amazon world today. The pandemic certainly accelerated some of the structural changes and put a spotlight on supply chain issues. Just like consumers, wholesalers and retailers want product all the time so it’s essential for growers to keep up the pace of demand or risk losing business.

The bottom line is that all farming is economies of scale. To consistently produce every day of the week and be sustainable, reliable, and dependable for your customers –whether you’re a small niche grower or a mega-grower– is hard work. At Schuyler Greens and Better Future Farms, we’re committed to meeting the needs of our customers and partners and are excited about the future.

To learn more about Better Future Farms, visit www.betterfuture.farm

To learn more about Schuyler Greens, visit www.schuylergreens.com

Freight Farms has seen incredible growth in the adoption of their technology in the Caribbean islands, many of which face challenges similar to the Cayman Islands’. From Turks and Caicos to the Bahamas, islanders are discovering the power of controlled environment agriculture to revolutionize food quality and access for themselves and their communities.

Freight Farms has seen incredible growth in the adoption of their technology in the Caribbean islands, many of which face challenges similar to the Cayman Islands’. From Turks and Caicos to the Bahamas, islanders are discovering the power of controlled environment agriculture to revolutionize food quality and access for themselves and their communities.

Founded in 2012, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container with the mission of democratizing and decentralizing the local production of fresh, healthy food. Since its inception, Freight Farms has refined its product offering to arrive at the Greenery™ S container farm. With global customers ranging from small business farmers to the corporate, hospitality, retail, education, and nonprofit sectors, Freight Farmers make up the largest network of connected farms in the world. AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software.

Founded in 2012, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container with the mission of democratizing and decentralizing the local production of fresh, healthy food. Since its inception, Freight Farms has refined its product offering to arrive at the Greenery™ S container farm. With global customers ranging from small business farmers to the corporate, hospitality, retail, education, and nonprofit sectors, Freight Farmers make up the largest network of connected farms in the world. AgTech Breakthrough named Freight Farms the 2022 “IoT Monitoring Solution of the Year” for its farmhand® IoT automation software.

“We made it a mandate when we started ColdAcre that we wouldn’t contribute to the single-use plastics problem that’s top of mind for many Canadians. We’ve been very pleased to be able to work with our like-minded partner good natured® as we prepare to triple our production in the coming months and offer our products in plant-based, compostable packaging,” said Tarek Bos-Jabber, CEO of ColdAcre.

“We made it a mandate when we started ColdAcre that we wouldn’t contribute to the single-use plastics problem that’s top of mind for many Canadians. We’ve been very pleased to be able to work with our like-minded partner good natured® as we prepare to triple our production in the coming months and offer our products in plant-based, compostable packaging,” said Tarek Bos-Jabber, CEO of ColdAcre.

As we gear up for the new

As we gear up for the new  The US lags far behind many other countries in the aquaculture production, currently ranking 17th in total output. The US is not competitive for several reasons, including but not limited to stringent environmental regulations, NIMBY attitudes, and high labor costs, all of which are solved by RAS. Bringing the entire process into a controlled environment, we manage all inputs and outflows from our operations. With much better bio-security, we have not had an outbreak or disease event in twenty years. In fact, we have been certified disease free by independent fish veterinarians every year since 2013.

The US lags far behind many other countries in the aquaculture production, currently ranking 17th in total output. The US is not competitive for several reasons, including but not limited to stringent environmental regulations, NIMBY attitudes, and high labor costs, all of which are solved by RAS. Bringing the entire process into a controlled environment, we manage all inputs and outflows from our operations. With much better bio-security, we have not had an outbreak or disease event in twenty years. In fact, we have been certified disease free by independent fish veterinarians every year since 2013. Aquaponics is an obvious extension of our current operations, and we have been working towards adding this component to our operations for some time. We have performed several small-scale R&D projects over the years, with favorable results.

Aquaponics is an obvious extension of our current operations, and we have been working towards adding this component to our operations for some time. We have performed several small-scale R&D projects over the years, with favorable results. Blue Ridge Aquaculture has a long history in the US Aquaculture and the global RAS community. It is important for us to build that same presence in this industry. We will continue to support Virginia as a leader in CEA and AgTech. Virginia Tech has been a tremendous resource for our company assisting our growth and development over the years. We anticipate Virginia Tech and the IALR will be an important asset as we grow into this space as well. Because of that collaboration, it was important for us to support their outreach efforts and this conference.

Blue Ridge Aquaculture has a long history in the US Aquaculture and the global RAS community. It is important for us to build that same presence in this industry. We will continue to support Virginia as a leader in CEA and AgTech. Virginia Tech has been a tremendous resource for our company assisting our growth and development over the years. We anticipate Virginia Tech and the IALR will be an important asset as we grow into this space as well. Because of that collaboration, it was important for us to support their outreach efforts and this conference. So in 2003, the company created a wholly owned subsidiary for the dedicated delivery of all of its product- problems solved. In 2017, the company built its own feed mill to control the quality and supply of feed for all operations. That gave us control over our biggest operating input.

So in 2003, the company created a wholly owned subsidiary for the dedicated delivery of all of its product- problems solved. In 2017, the company built its own feed mill to control the quality and supply of feed for all operations. That gave us control over our biggest operating input.

Vertical farming technology provider

Vertical farming technology provider  We call ourselves the one-stop shop for vertical farming, which means that on top of our proprietary Vera® technology we offer all services and support needed to build a commercially viable vertical farming business. This means we provide our customers with the design and planning of their facility, we ship the equipment, and we build, install and commission the farm. We support our customers in getting their farm up to production volumes. We also provide a five-year maintenance agreement to ensure the technology performs optimally.

We call ourselves the one-stop shop for vertical farming, which means that on top of our proprietary Vera® technology we offer all services and support needed to build a commercially viable vertical farming business. This means we provide our customers with the design and planning of their facility, we ship the equipment, and we build, install and commission the farm. We support our customers in getting their farm up to production volumes. We also provide a five-year maintenance agreement to ensure the technology performs optimally.

Netled’s Vera® technology is designed to be as energy and resource-efficient as possible using up to 70% less energy and up to 95% less water than traditional indoor agriculture. It also allows customers to grow 2.5 times more crops in the same amount of space as greenhouse growing.

Netled’s Vera® technology is designed to be as energy and resource-efficient as possible using up to 70% less energy and up to 95% less water than traditional indoor agriculture. It also allows customers to grow 2.5 times more crops in the same amount of space as greenhouse growing. In terms of other projects, we have just finished commissioning a compact-size Vera® farm in Poland, and we are currently building another industrial-scale facility in the Nordics. We are in the negotiating phase with other clients on some very exciting commercial-scale projects in Europe and North America, stay tuned for more details!

In terms of other projects, we have just finished commissioning a compact-size Vera® farm in Poland, and we are currently building another industrial-scale facility in the Nordics. We are in the negotiating phase with other clients on some very exciting commercial-scale projects in Europe and North America, stay tuned for more details!

From the recent opening of its largest, most technologically advanced sustainable commercial smart farm in Bethlehem, Pennsylvania to its expansion into fruiting and vine crops with the launch of new strawberry varieties ,

From the recent opening of its largest, most technologically advanced sustainable commercial smart farm in Bethlehem, Pennsylvania to its expansion into fruiting and vine crops with the launch of new strawberry varieties ,  Investment in CEA comes down to two words: resiliency and sustainability. The past two years have made it painfully clear that climate change, global events, and supply chain disruption all have an enormous impact on our food systems. We need resiliency now more than ever before. By growing indoors, 365 days a year, with zero impact from drought, wildfires, or extreme temperatures, Bowery is growing a resilient supply of pesticide-free produce. And not only resilient, but predictable and reliable—we know, and therefore retailers know, exactly how much produce to expect, which cuts down on food waste.

Investment in CEA comes down to two words: resiliency and sustainability. The past two years have made it painfully clear that climate change, global events, and supply chain disruption all have an enormous impact on our food systems. We need resiliency now more than ever before. By growing indoors, 365 days a year, with zero impact from drought, wildfires, or extreme temperatures, Bowery is growing a resilient supply of pesticide-free produce. And not only resilient, but predictable and reliable—we know, and therefore retailers know, exactly how much produce to expect, which cuts down on food waste.

Bethlehem represents the next chapter in climate-smart agriculture at Bowery. The Bethlehem Farm, once a non-arable industrial site, is now modern farmland. This transformation from brownfield to vertical farm means that fresh, healthy food is now being grown, year-round, where it was previously thought no food would ever grow again.

Bethlehem represents the next chapter in climate-smart agriculture at Bowery. The Bethlehem Farm, once a non-arable industrial site, is now modern farmland. This transformation from brownfield to vertical farm means that fresh, healthy food is now being grown, year-round, where it was previously thought no food would ever grow again. Over the course of my career, so many talented women leaders helped shape and inspire my path. I wouldn’t be where I am today without their encouragement and support. This background, where women fiercely support one another, led me to co-found aGirlculture at Bowery. The group brings together women of all levels to connect with peers and senior leaders. We’re creating a space for mentorship and other opportunities for personal and professional growth.

Over the course of my career, so many talented women leaders helped shape and inspire my path. I wouldn’t be where I am today without their encouragement and support. This background, where women fiercely support one another, led me to co-found aGirlculture at Bowery. The group brings together women of all levels to connect with peers and senior leaders. We’re creating a space for mentorship and other opportunities for personal and professional growth. The Bethlehem Farm, our Smart Farm of the Future, is a model for what’s next at Bowery. We have two additional farms under construction in Locust Grove, Georgia and Arlington, Texas and we’re on track to double our number of farms by 2023, with the goal of helping to alleviate the strains insecurity puts on the U.S. food supply and economy.

The Bethlehem Farm, our Smart Farm of the Future, is a model for what’s next at Bowery. We have two additional farms under construction in Locust Grove, Georgia and Arlington, Texas and we’re on track to double our number of farms by 2023, with the goal of helping to alleviate the strains insecurity puts on the U.S. food supply and economy.

What started in 2011 as a dream to deliver fresh, nutritious produce to Canadians year-round has become reality. As Canada’s first and largest commercial vertical farming operation,

What started in 2011 as a dream to deliver fresh, nutritious produce to Canadians year-round has become reality. As Canada’s first and largest commercial vertical farming operation,  We are currently growing microgreens — Spicy Mustard Medley, Pea Shoots, Asian Blend, Micro Arugula, Micro Radish, and Micro Broccoli — and baby greens – Ontario Arugula, Ontario Spring Mix and Ontario Baby Spinach.

We are currently growing microgreens — Spicy Mustard Medley, Pea Shoots, Asian Blend, Micro Arugula, Micro Radish, and Micro Broccoli — and baby greens – Ontario Arugula, Ontario Spring Mix and Ontario Baby Spinach. Our sustainable practices include:

Our sustainable practices include: Construction on our Calgary farm is well under way. We are on schedule to have the 95,000-square-foot farm open and providing fresh leafy greens to grocery stores across Western Canada in first half of next year.

Construction on our Calgary farm is well under way. We are on schedule to have the 95,000-square-foot farm open and providing fresh leafy greens to grocery stores across Western Canada in first half of next year. We are constantly innovating and experimenting with new processes and products to bring the best possible leafy greens to Canadian consumers.

We are constantly innovating and experimenting with new processes and products to bring the best possible leafy greens to Canadian consumers.