Revolutionizing Agriculture: Indoor Vertical Farming With Pipp Horticulture | Planted Detroit Case Study

Pipp Horticulture has quickly become an industry-leading Mobile Vertical Growing Solutions provider, with installations in over 2,500 grow rooms worldwide. Pipp’s Mobile Vertical Grow Racks allow cultivators to maximize production capability, reduce operating costs, and increase overall revenue per square foot by maximizing their cubic canopy footprint without increasing the square footprint of the room or building. Pipp takes pride in manufacturing all its products in the USA.

Although Pipp’s entry point into the horticulture industry was through the cannabis market, Pipp Horticulture is not limited to any specific cultivation or plant processing category.

Instead, the company looks forward to leveraging the knowledge and experience gained through the cannabis industry to develop solutions for all growers. Pipp sees tremendous growth ahead. Rooted in what indoor cultivation will mean to families, cities, and the world. The possibilities are limitless.

Over the years, Pipp has strategically acquired several industry leaders in the market to create a well-rounded cultivation solution. These companies include Greenhaus Industries, Vertical Air Solutions, GGS Structures, and the assets of Grow Glide. Each of these strategic acquisitions aims to provide purpose-built solutions to support all aspects of your grow facility. Through these acquisitions, Pipp has assembled a team of highly experienced cultivators.

Pipp experts work with the company’s engineers and designers to develop innovations built for the indoor vertical farming market. They also support Pipp customers before, during, and after installation. They offer expert advice and help educate the community on best practices for building and operating your indoor vertical farm.

Planted Detroit Case Study:

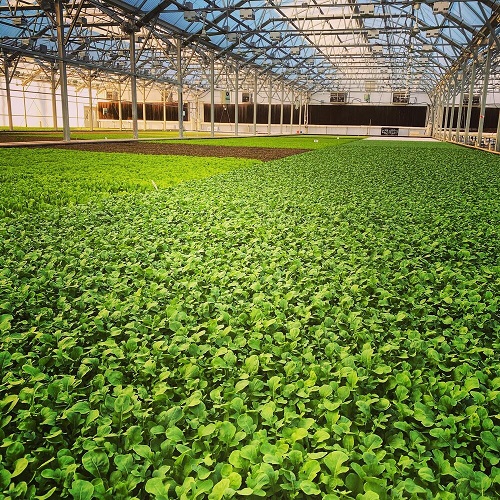

Planted Detroit, located in Detroit, Michigan, is a 20,000-square-foot warehouse with two grow rooms equipped with two types of LED lighting, two hydroponic systems, and a single database system for data collection and analysis. Their mission is to actively work to reduce food insecurity in their communities and come together to grow tastier, healthier, and more accessible greens sustainably.

Planted Detroit is moving ahead with Pipp Horticulture as its primary provider of racking systems due to its versatility which allowed Planted Detroit to add advanced ebb-and-flow hydroponic technology to the racking system.

Pipp engineers and installation experts worked with Planted Detroit to install mobile vertical grow racking systems that were clean and biosecure. The Pipp team helped implement a controlled environment agriculture (CEA) system to help better serve their community regardless of the season. Planted Detroit wants to ensure they grow only the best greens, monitoring every aspect of their environment.

After implementing Pipp’s mobile vertical grow racking systems, Planted Detroit can quickly access and tend to all their plants and grow 8x more. They cultivate their fresh greens on Pipp’s mechanical-assist carriages, holding eight tiers of plants while utilizing 3,000 ABS combination grow trays. Pipp then helped further increase the efficiency of Planted Detroit’s growing systems with our ELEVATE® Platform System to help maintain and care for all their plants on each grow level.

All photos courtesy of EE Berger/Planted Detroit

For more information visit Pipp Horticulture

The decision was driven by both the site and infrastructure. My business partner David Drescher and I both live in the Charlottesville area, and Louisa County is the next county over. In central Virginia it’s hard to find the flat terrain needed for a greenhouse facility. This site had that and the right infrastructure in place in terms of electrical capabilities, natural gas, and proximity to large freeways and distribution logistics.

The decision was driven by both the site and infrastructure. My business partner David Drescher and I both live in the Charlottesville area, and Louisa County is the next county over. In central Virginia it’s hard to find the flat terrain needed for a greenhouse facility. This site had that and the right infrastructure in place in terms of electrical capabilities, natural gas, and proximity to large freeways and distribution logistics. Taylor Farms is one of the largest salad and fresh cut vegetable processors in the world and all our lettuce will be marketed under Taylor Farms’ Earthbound Farms brand. David and I have both been at this for a long time and we know what it takes to build a brand. So, we wanted to team up with an existing brand rather than build a new one from scratch. We talked to several companies and when we met with Taylor Farms, our objectives, philosophies, and values all aligned.

Taylor Farms is one of the largest salad and fresh cut vegetable processors in the world and all our lettuce will be marketed under Taylor Farms’ Earthbound Farms brand. David and I have both been at this for a long time and we know what it takes to build a brand. So, we wanted to team up with an existing brand rather than build a new one from scratch. We talked to several companies and when we met with Taylor Farms, our objectives, philosophies, and values all aligned. Generate Capital is a leading ESG public benefit corporation focused heavily on building and financing solutions for clean energy, water, waste, agriculture and more. They’d been looking at the CEA sector for some time. While we are their first investment here, I expect they will be very active in this space, and not just with us.

Generate Capital is a leading ESG public benefit corporation focused heavily on building and financing solutions for clean energy, water, waste, agriculture and more. They’d been looking at the CEA sector for some time. While we are their first investment here, I expect they will be very active in this space, and not just with us. I wouldn’t be doing this new project without the knowledge and experience I gained from launching and building Schuyler Greens. I’ve owned Schuyler Greens for more than 9 years now and it encompasses 225 acres outside of Charlottesville with a greenhouse in the middle. I will be keeping Schuyler Greens separate from Better Future Farms.

I wouldn’t be doing this new project without the knowledge and experience I gained from launching and building Schuyler Greens. I’ve owned Schuyler Greens for more than 9 years now and it encompasses 225 acres outside of Charlottesville with a greenhouse in the middle. I will be keeping Schuyler Greens separate from Better Future Farms.

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised.

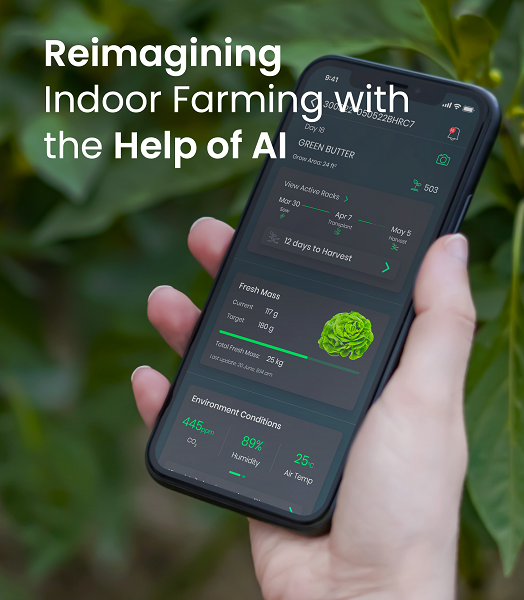

The most significant challenge we see is the need to reach profitability. We’ve all seen the recent headlines of farms shutting down, being delisted, or going through intensely difficult and desperate financial times. We’re starting to see that for many stakeholders, the hype is waning, the honeymoon is over, and investors want to see a return on their investment – or at least a very substantive and believable path to it. For CEA to truly become commercially viable and scalable, farmers need systems and support that help them produce a marketable product in a reasonable timeframe, and with enough margins to see a profit. As an industry, we need to focus more on celebrating the farms that reach profitability and less on how much money has been raised. AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable.

AI is evolving faster than any other technology we’ve ever seen. Generative AI like ChatGPT can produce an entire screenplay or write the code for a new app in a matter of minutes. However, the current version is already being replaced with an even more powerful version, GPT-4, which is said to be capable of creating full movies from simple text prompts. This massive jump in performance is due to a 10x increase in data parameters used for training. At AGEYE, we believe the future of indoor farming is data-driven, and our commitment to this goal drives everything we do. In 2019 we started training our vision models to detect crop stress. Fast forward to today, and we’ve expanded our AI platform to cover every aspect of an indoor farm. We’re collecting thousands of data points per plant, per cycle, that we aggerate with environment, energy, and labor data to produce powerful insights and unprecedented visibility across an entire operation. We’re empowering growers with the technology and tools they need to become efficient, sustainable, and, most importantly, profitable. There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

There are some very fundamental challenges that come with any installation, and while each installation is a bit different, many things we see are common. In the Nebraska installation, we will be retrofitting an existing building. This is quite common. One could argue that an optimal vertical farm would be created in a building specifically designed for vertical farming because everything from airflow to automation and intelligence would fit perfectly into a well-designed and very intentional space. This removes some of the challenges of altering what can sometimes seem like a square peg that needs to be implemented into a round hole. But, realistically speaking, there are real benefits to also retrofitting an existing building. We’re good enough at understanding what has to happen to know if it can successfully happen. A perfect building might be beyond the reach of many people who want to enter vertical indoor farming, while an existing space might mean that someone doesn’t need tens of millions of dollars to set up a successful indoor commercial farm. Repurposing buildings has an inherent appeal in that you are taking something that could be non-productive and turning it into something very productive at a cost point that makes sense for the owner and can create something beneficial in terms of actual production or job creation.

Delivering “Greenhouse-as-a-Service” (GaaS), EGT designs, engineers and manufactures vertical greenhouses to help grow large amounts of fresh food that can be sourced locally. The company partnered with PathoSans because unlike traditional caustic cleaning chemicals, PathoSans’ ECAS technology produces a cleaner and disinfectant using just salt, water and electricity. It contains no added fragrances and is safe for use on foods and in food preparation. In addition, the disinfectant eliminates pathogens and molds that can exist on food, where food grows, and in food packaging and preparation areas.

Delivering “Greenhouse-as-a-Service” (GaaS), EGT designs, engineers and manufactures vertical greenhouses to help grow large amounts of fresh food that can be sourced locally. The company partnered with PathoSans because unlike traditional caustic cleaning chemicals, PathoSans’ ECAS technology produces a cleaner and disinfectant using just salt, water and electricity. It contains no added fragrances and is safe for use on foods and in food preparation. In addition, the disinfectant eliminates pathogens and molds that can exist on food, where food grows, and in food packaging and preparation areas. “Food safety is our top priority at EGT and it governs each of our processes,” said Aaron Fields, Director of Horticulture at Eden Green Technology Fields. “That’s why we chose PathoSans to ensure our operations use safe and effective cleaning solutions. PathoSans shares our mission of delivering innovative technology with a focus on social responsibility, safety, self-sufficiency, and sustainability.”

“Food safety is our top priority at EGT and it governs each of our processes,” said Aaron Fields, Director of Horticulture at Eden Green Technology Fields. “That’s why we chose PathoSans to ensure our operations use safe and effective cleaning solutions. PathoSans shares our mission of delivering innovative technology with a focus on social responsibility, safety, self-sufficiency, and sustainability.” Through its partnership with PathoSans, EGT can also fulfill its mission of providing greenhouses and services that reduce waste, water consumption and reliance on greenhouse gas emissions. On-site generation of cleaning and disinfecting solutions allows EGT and its clients to refill spray bottles and reduce plastic waste. Without relying on chemical supply chains, EGT further shrinks its carbon footprint by eliminating chemical transportation, storage and disposal. Additionally, since PathoSans solutions leave no chemical residue behind on surfaces, greenhouses can save water since less rinsing is required.

Through its partnership with PathoSans, EGT can also fulfill its mission of providing greenhouses and services that reduce waste, water consumption and reliance on greenhouse gas emissions. On-site generation of cleaning and disinfecting solutions allows EGT and its clients to refill spray bottles and reduce plastic waste. Without relying on chemical supply chains, EGT further shrinks its carbon footprint by eliminating chemical transportation, storage and disposal. Additionally, since PathoSans solutions leave no chemical residue behind on surfaces, greenhouses can save water since less rinsing is required.