Q&A With James Eaves, Indoor Agriculture Director, Voltserver

In an era where innovation and sustainability are paramount in the agricultural industry, one technology is disrupting the way we think about electrical power distribution. VoltServer, the pioneer of Digital Electricity™, is leading the charge with its groundbreaking approach to powering CEA. Indoor Ag-Con talked with VoltServer’s Indoor Agriculture Director James Eaves ahead of September’s CEA Summit East where he will be leading a panel discussion exploring the potential of Class 4 Power—a new power classification specifically tailored for Digital Electricity – in the realm of CEA. Read on as he demystifies Digital Electricity, discusses its advantages over traditional power distribution methods, explores real-world implementations, and shares insights into VoltServer’s future plans for advancing this revolutionary technology in the agricultural sector.

Can you explain in simple terms what Digital Electricity (Class 4 Power) is and how it differs from traditional electrical distribution systems?

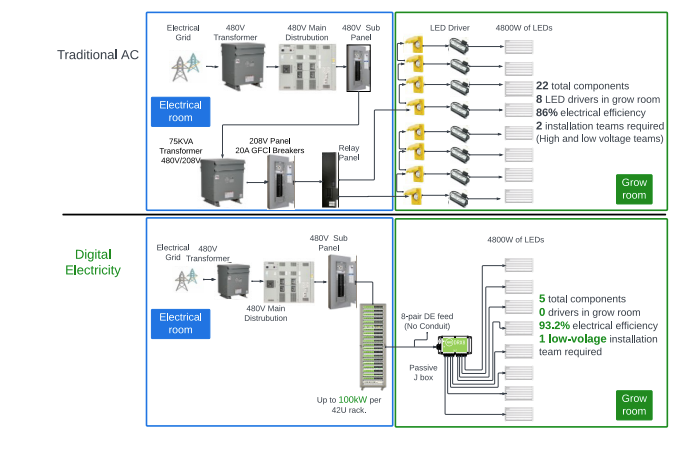

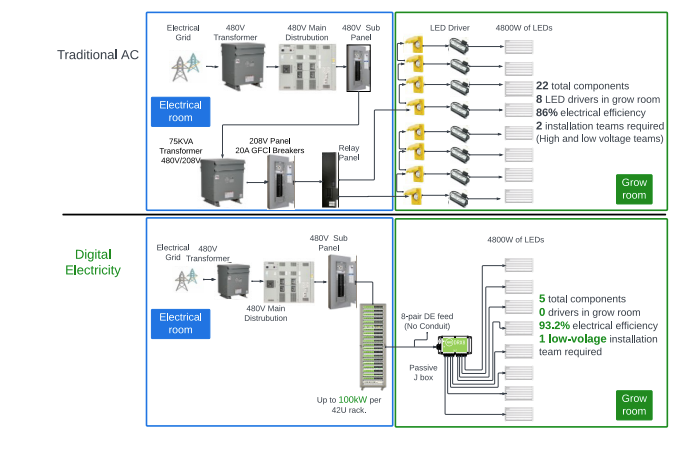

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

On the other hand, Digital Electricity eliminates the need for all those things. It transforms your electrical system from a complicated infrastructure controlled by outside contractors or facility managers into something more like an IT appliance controlled by IT teams. This means that the installation and management of Digital Electricity are simpler and more user-friendly. Digital Electricity has caused a significant disruption in the market.

It has been so groundbreaking that the National Electric Code, which sets safety standards for electrical systems, has introduced a new power classification called “Class 4 Power” specifically for Digital Electricity. This shows how much of an impact Digital Electricity has had on the industry, as it represents the first new power classification in 70 years.

What specific advantages does Digital Electricity offer to CEA operators compared with traditional power distribution methods?

The most common use case is the significant reduction in cost, complexity, and time required to distribute high voltage electricity to horticulture LEDs, fans, pumps, sensors, and irrigation solenoids. For example, Digital Electricity eliminates over 75% of the components required to distribute power to LED, including LED drivers in grow spaces. Moreover, it can be installed in around 1/10th the time.

Digital Electricity also provides growers with unprecedented control and monitoring capabilities. Unlike traditional systems, with Digital Electricity, growers can control, monitor, and schedule each individual LED without installing a second set of wires and equipment. The grower uses software to group LEDs into zones, which can be easily changed as needed. If there is an issue with an LED, the grower receives an instant notification. Other features include the ability to audit power usage for each zone and automatically respond to electricity utilities’ demand response signals, which can create a significant new revenue source for the company.

Can you share a real-world example of how VoltsServer’s Digital Electricity has been implemented in a vertical farm or greenhouse, and the resulting benefits observed by the operator?

Hardee Fresh , a large CEA company, has successfully implemented Digital Electricity in their operations. They have utilized this innovative power distribution system to power the LEDs in the world’s largest certified organic vertical farm. Recently, they embarked on constructing a new facility in Georgia, spanning approximately 350,000 square feet and capable of producing an impressive 15 million heads of lettuce annually. Both of their facilities rely heavily on adjacent solar farms for power generation.

, a large CEA company, has successfully implemented Digital Electricity in their operations. They have utilized this innovative power distribution system to power the LEDs in the world’s largest certified organic vertical farm. Recently, they embarked on constructing a new facility in Georgia, spanning approximately 350,000 square feet and capable of producing an impressive 15 million heads of lettuce annually. Both of their facilities rely heavily on adjacent solar farms for power generation.

The implementation of a complex and expensive electrical infrastructure would have posed significant challenges. However, thanks to the plug-and-play nature of Digital Electricity, Hardee Fresh was able to swiftly install, maintain, and operate their entire electrical system using their own workforce. This not only saved them a substantial amount of time but also significantly reduced the need for extensive equipment typically required in such projects. This advantage is particularly valuable in the current environment, where there are long lead times for contractors and electrical components like panels and step-down transformers.

In addition to streamlining the deployment process and reducing capital expenditures, Hardee Fresh places great importance on energy efficiency. Digital Electricity has enabled them to enhance energy efficiency through better system design. Moreover, it has provided them with highly precise control and monitoring capabilities over their LEDs, allowing for further cost reduction while maintaining optimal performance.

As the first company to patent and commercialize this innovative technology, what are Voltserver’s plans for future advancements in Digital Electricity and its applications in the agricultural sector?

We are deeply committed to the CEA industry and aim to contribute by making it more financially and environmentally sustainable. Our goal is to power everything in a vertical farm or greenhouse, making the construction and maintenance aspects much easier. After getting CAPEX under control, the promise of CEA will lie in implementing software and connected devices to decrease the cost of producing high-quality food. However, many equipment companies keep their systems closed, hindering innovation in the industry. The intelligence of Digital Electricity presents a unique opportunity to develop powerful software applications, many that we can’t even imagine today. We have intentionally designed our system to be open, allowing anyone to use our open API to develop their own software tools. Currently, we are collaborating with large energy and technology partners to create new software tools that provide growers with even more control over their growing environments and energy usage.

At the upcoming CEA Summit East, you will be leading a panel discussion on Class 4 Power. Can you give our readers a sneak preview of some of the areas you plan to cover during this session?

During the CEA Summit East panel discussion, our goal is to provide the audience with a brief introduction to Class 4 Power, its benefits for the CEA industry, and the potential for Class 4 to become the new standard in CEA design and construction. The panel will include leaders from the electrical construction, LED, and vertical farming industries.

Learn more about Voltserver and the many benefits of Class 4 power by attending CEA Summit East September 19-20, 2023 at the Institute for Advance Learning & Research Conference Center. Early Bird registration rates are still available!

You can also learn more about Voltserver by visiting the company website here.

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

Digital Electricity is a new approach to electrical power distribution that uses advanced digital technology. It is based on the concept of transmitting power as high voltage Direct Current (DC) rather than traditional Alternating Current (AC).The main difference between Digital Electricity and traditional electricity is how they are installed and used. Traditional high voltage DC or Alternating Current (AC) requires expensive and time-consuming wiring methods and safety equipment like licensed labor, inspections, permits, and specific devices such as breakers, ground fault protection, and step-down transformers.

Workshop instructors include Dr. Karl Kolb, president of Ceres University and Ceres Certifications, International (CCI) and Kellie Worrell, GlobalG.A.P. Scheme Manager, CCI. Dr. Kolb is a microbiologist with a quality background and more than 30 years as an industry professional. In addition to her current role with CCI, Kellie Worrell has managed the Food Safety Program for multiple vegetable farms, including a wide variety of crops. CCI features GLOBALG.A.P. among its many GFSI food safety schemes.

Workshop instructors include Dr. Karl Kolb, president of Ceres University and Ceres Certifications, International (CCI) and Kellie Worrell, GlobalG.A.P. Scheme Manager, CCI. Dr. Kolb is a microbiologist with a quality background and more than 30 years as an industry professional. In addition to her current role with CCI, Kellie Worrell has managed the Food Safety Program for multiple vegetable farms, including a wide variety of crops. CCI features GLOBALG.A.P. among its many GFSI food safety schemes.

Harnessing the power of existing genetics and strategic collaborations,

Harnessing the power of existing genetics and strategic collaborations,  Tell us about the main goals and objectives of Sakata Seed’s CEA division? How does it support the needs and demands of greenhouse grower, vertical farm operators and other indoor growers in the sector?

Tell us about the main goals and objectives of Sakata Seed’s CEA division? How does it support the needs and demands of greenhouse grower, vertical farm operators and other indoor growers in the sector? Could you provide a couple of examples of Sakata Seed’s varieties that have shown exceptional performance in indoor growing environments, and what attributes make them well-suited for CEA?

Could you provide a couple of examples of Sakata Seed’s varieties that have shown exceptional performance in indoor growing environments, and what attributes make them well-suited for CEA? Share some insights into the unique challenges and opportunities that CEA presents for seed development and production, compared to traditional outdoor farming?

Share some insights into the unique challenges and opportunities that CEA presents for seed development and production, compared to traditional outdoor farming? How do you identify and prioritize the traits and characteristics that are more important for indoor growers — are you able to collaborate with growers to gather feedback and insights?

How do you identify and prioritize the traits and characteristics that are more important for indoor growers — are you able to collaborate with growers to gather feedback and insights? Can you highlight any recent advancements or innovations in seed development within your CEA division? What varieties or technologies can growers anticipate from Sakata Seed in the near future.

Can you highlight any recent advancements or innovations in seed development within your CEA division? What varieties or technologies can growers anticipate from Sakata Seed in the near future.

The concept of Vertical Farming is not as contemporary as it might seem, with roots plunging deep into ancient history, as far back as the Hanging Gardens of Babylon in 605 BCE. However, it wasn’t until the 20th century that it truly began to blossom as a practical method of farming. The turning point was during WWII, when hydroponics—a subset of Vertical Farming—was employed on a large scale to feed the Allied Forces in the South Pacific, yielding over 8,000 tons of produce. The concept was refined further at Columbia University between 1991 and 1999, under the guidance of Professor Dr. Dickson Despommier. Now hailed as the father of modern Vertical Farming, Despommier and his students successfully devised a way to sustainably feed New York City’s populace via rooftop agriculture, birthing the contemporary approach to multi-story farming.

The concept of Vertical Farming is not as contemporary as it might seem, with roots plunging deep into ancient history, as far back as the Hanging Gardens of Babylon in 605 BCE. However, it wasn’t until the 20th century that it truly began to blossom as a practical method of farming. The turning point was during WWII, when hydroponics—a subset of Vertical Farming—was employed on a large scale to feed the Allied Forces in the South Pacific, yielding over 8,000 tons of produce. The concept was refined further at Columbia University between 1991 and 1999, under the guidance of Professor Dr. Dickson Despommier. Now hailed as the father of modern Vertical Farming, Despommier and his students successfully devised a way to sustainably feed New York City’s populace via rooftop agriculture, birthing the contemporary approach to multi-story farming.

Hydrofarm Holdings Group, Inc.

Hydrofarm Holdings Group, Inc.

One of Winter Farm’s goals is to help growers replace 10% of Canada’s strawberry imports. Can you speak to some of the environmental and economic benefits that could come from achieving this goal, and how Winter Farm is working to make it a reality?

One of Winter Farm’s goals is to help growers replace 10% of Canada’s strawberry imports. Can you speak to some of the environmental and economic benefits that could come from achieving this goal, and how Winter Farm is working to make it a reality?

What do you see as the biggest opportunities for the CEA industry as a whole in years to come, and how is Winter Farm working to seize them?

What do you see as the biggest opportunities for the CEA industry as a whole in years to come, and how is Winter Farm working to seize them?

The

The

The

The