Where Agriculture Meets Wellness: Q&A With Seed2Source Founder Jennifer Waxman

After successfully guiding The Villages Grown™ to its current position as a vertically integrated, 84-acre total footprint, controlled environment agriculture (CEA), year-round, produce growing operation in Central Florida, Jennifer Waxman is heading back to her roots. That is, she’s turning her focus back to Seed2Source, the firm she launched in 2005 driven by her “agriculture meets wellness” passion and vision.

After successfully guiding The Villages Grown™ to its current position as a vertically integrated, 84-acre total footprint, controlled environment agriculture (CEA), year-round, produce growing operation in Central Florida, Jennifer Waxman is heading back to her roots. That is, she’s turning her focus back to Seed2Source, the firm she launched in 2005 driven by her “agriculture meets wellness” passion and vision.

Indoor Ag-Con is thrilled to have Jennifer on our Advisory Board, as a speaker at the upcoming CEA Summit East in Virginia next week , and Indoor Ag-Con in Las Vegas in February 2023. We had the chance to catch up with this busy CEA industry leader to learn more about her vision and plans in this month’s Q&A

For the last 6 years, you’ve overseen the impressive growth and development of The Villages Grown. Why was the timing right to leave that post to focus on Seed2Source?

We were given the honor and trust to carry out our vision and model for The Villages Grown. This included the strategic direction, design, construction, and operation of a first-of-kind CEA in the South. We backed this with educational programming from both B2C and B2B. We built a community-based brand yet grew enough product for expansion throughout Florida. We worked with beautiful people in a beautiful community.

We were given the honor and trust to carry out our vision and model for The Villages Grown. This included the strategic direction, design, construction, and operation of a first-of-kind CEA in the South. We backed this with educational programming from both B2C and B2B. We built a community-based brand yet grew enough product for expansion throughout Florida. We worked with beautiful people in a beautiful community.

However, it is no secret that CEA is only scratching the surface in the US. We knew we wanted to be at the head of the ride with its growth. Several players in the CEA sector were showing intrigue and interest in our model. I believe this was rooted in our ability to build a strong brand, educate, all the while supporting other local farmers along the way.

I’ve learned a lot since entering the hydroponics sector in 2000. This is when I started to conceive this model of holistic wellness and was based on my global travels, thus observing the ‘Future of Food’. There is a lot to share from a rather long career in this sector. I have experienced successes, failures, and have observed overall industry needs and voids. This is the exciting part and I wanted back in!

Share more about Seed2Source, your Sustainable Ag Business Consulting Firm focusing on controlled environment agriculture

Seed2Source launched in 2016 but was really an evolution of my first ‘Agriculture Meets Wellness’ firm which was launched in 2005. Seed2Source is a first-of-kind, Sustainable Agriculture & Wellness, consulting firm headquartered in Florida but serving the US (and beyond). The firm focuses on strategic CEA projects rooted in sustainable agricultural, food-as-medicine, and local food system models.

Seed2Source launched in 2016 but was really an evolution of my first ‘Agriculture Meets Wellness’ firm which was launched in 2005. Seed2Source is a first-of-kind, Sustainable Agriculture & Wellness, consulting firm headquartered in Florida but serving the US (and beyond). The firm focuses on strategic CEA projects rooted in sustainable agricultural, food-as-medicine, and local food system models.

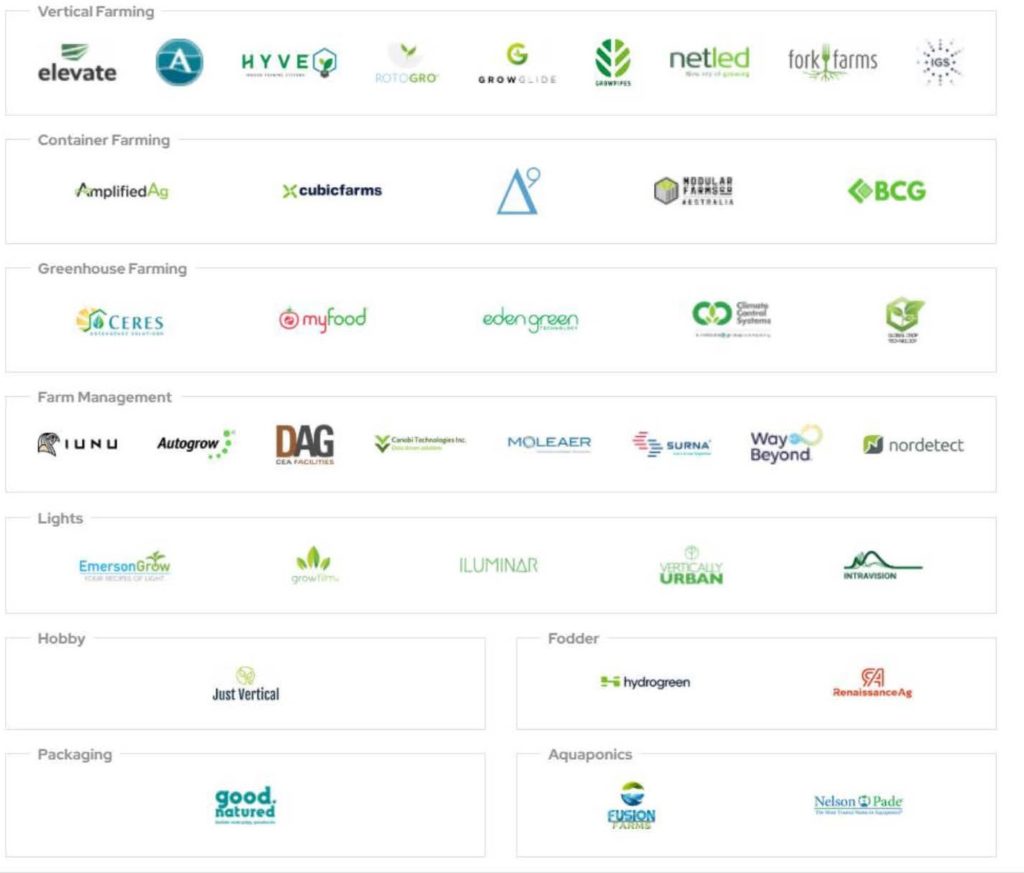

Our CEA experience includes Vertical Farming, Controlled Greenhouse, Aeroponic and Hydroponic Methodologies, Strategy, Branding, Distribution, Education, Innovation, and Science. We are a one-stop-shop and are surrounded by the best and the brightest in all operational units required for true success. We bring in different consultants as the projects deem fit. This allows us to take on both small and large projects as the market dictates.

At the upcoming CEA Summit, you’ll be speaking on 2 panels, including one titled “Building The Future of CEA”. If there is one message you hope to get across on that panel discussion what is it?

The CEA industry is still at its infancy and shall evolve with continuous iterations and innovations. Typically, when most people think of CEA, they only think of High-Tech, AI, Automation, etc. and forget about the State of Agriculture in general. I hope people start to realize that CEA is ‘part’ of a solution and not the ‘only’ solution. Also, I hope that people don’t forget about the actual agriculturists and horticulturists that are the true heroes in creating a sustainable, profitable, CEA operation. This seems to be lost with many of the current players in CEA.

The CEA industry is still at its infancy and shall evolve with continuous iterations and innovations. Typically, when most people think of CEA, they only think of High-Tech, AI, Automation, etc. and forget about the State of Agriculture in general. I hope people start to realize that CEA is ‘part’ of a solution and not the ‘only’ solution. Also, I hope that people don’t forget about the actual agriculturists and horticulturists that are the true heroes in creating a sustainable, profitable, CEA operation. This seems to be lost with many of the current players in CEA.

You’ll also be speaking at the 2023 edition of Indoor Ag-Con on a great session idea you brought to us, “Building A CEA Alliance: The Power of Grower Partnerships.” Can you share a little more about this idea?

As it stands, there is little-to-no diversity in US CEA. Everyone is clamoring for funding, market share, and innovations in technology. I believe they are missing a huge opportunity for collaborations, strategic partnerships, and supply chain solutions. We must work together not only for larger supply chain opportunities in both retail and wholesale, but to truly exchange best business practices and the like. We should also be collaborating to keep domestic supply in our own backyard and with prominence. There is enough business to be had for all!

What’s next for you and the team at Seed2Source?

What’s next for you and the team at Seed2Source?

Our vertically integrated CEA Model, of which we pride ourselves on, was clearly not an overnight success. We are still on this journey. This will continue to be the core of our mission and vision. The Vision – ‘Intersecting Agriculture with Wellness as a Food-As-Medicine Approach’ — will continue to drive our passion and expansion.

We feel strongly that this is the model for success and ultimate operational sustainability. We are being courted by some amazing operations – both new and old players in the CEA space – which has been rewarding. We will continue to build our CEA and overall Domestic Farm Partnerships and Educational Programming.

Learn more about Jennifer and her team at www.seed2source.com

Special thanks to Lori Culler for this post.

Special thanks to Lori Culler for this post.

As we gear up for the new

As we gear up for the new  The US lags far behind many other countries in the aquaculture production, currently ranking 17th in total output. The US is not competitive for several reasons, including but not limited to stringent environmental regulations, NIMBY attitudes, and high labor costs, all of which are solved by RAS. Bringing the entire process into a controlled environment, we manage all inputs and outflows from our operations. With much better bio-security, we have not had an outbreak or disease event in twenty years. In fact, we have been certified disease free by independent fish veterinarians every year since 2013.

The US lags far behind many other countries in the aquaculture production, currently ranking 17th in total output. The US is not competitive for several reasons, including but not limited to stringent environmental regulations, NIMBY attitudes, and high labor costs, all of which are solved by RAS. Bringing the entire process into a controlled environment, we manage all inputs and outflows from our operations. With much better bio-security, we have not had an outbreak or disease event in twenty years. In fact, we have been certified disease free by independent fish veterinarians every year since 2013. Aquaponics is an obvious extension of our current operations, and we have been working towards adding this component to our operations for some time. We have performed several small-scale R&D projects over the years, with favorable results.

Aquaponics is an obvious extension of our current operations, and we have been working towards adding this component to our operations for some time. We have performed several small-scale R&D projects over the years, with favorable results. Blue Ridge Aquaculture has a long history in the US Aquaculture and the global RAS community. It is important for us to build that same presence in this industry. We will continue to support Virginia as a leader in CEA and AgTech. Virginia Tech has been a tremendous resource for our company assisting our growth and development over the years. We anticipate Virginia Tech and the IALR will be an important asset as we grow into this space as well. Because of that collaboration, it was important for us to support their outreach efforts and this conference.

Blue Ridge Aquaculture has a long history in the US Aquaculture and the global RAS community. It is important for us to build that same presence in this industry. We will continue to support Virginia as a leader in CEA and AgTech. Virginia Tech has been a tremendous resource for our company assisting our growth and development over the years. We anticipate Virginia Tech and the IALR will be an important asset as we grow into this space as well. Because of that collaboration, it was important for us to support their outreach efforts and this conference. So in 2003, the company created a wholly owned subsidiary for the dedicated delivery of all of its product- problems solved. In 2017, the company built its own feed mill to control the quality and supply of feed for all operations. That gave us control over our biggest operating input.

So in 2003, the company created a wholly owned subsidiary for the dedicated delivery of all of its product- problems solved. In 2017, the company built its own feed mill to control the quality and supply of feed for all operations. That gave us control over our biggest operating input.

We recently announced the new partnership between

We recently announced the new partnership between  The Virginia Tech-IALR Controlled Environment Agriculture (CEA) Innovation Center was created to leverage the resources of the School of Plant and Environmental Sciences at the College of Agriculture and Life Sciences at Virginia Tech along with the biotechnology, technology, and analytical chemistry capabilities of IALR to move the CEA field forward. The Center offers a one-stop shop for many cutting-edge research projects and is a wonderful vehicle to support and attract industry partners. Part of the initiative is to also serve as a catalyst and hub for CEA companies and technology, and we are already helping to create an ecosystem around CEA innovation with some leading-edge projects in waste recycling, nutrient management, imaging and data analysis, and biotechnology. All of this will be facilitated by the

The Virginia Tech-IALR Controlled Environment Agriculture (CEA) Innovation Center was created to leverage the resources of the School of Plant and Environmental Sciences at the College of Agriculture and Life Sciences at Virginia Tech along with the biotechnology, technology, and analytical chemistry capabilities of IALR to move the CEA field forward. The Center offers a one-stop shop for many cutting-edge research projects and is a wonderful vehicle to support and attract industry partners. Part of the initiative is to also serve as a catalyst and hub for CEA companies and technology, and we are already helping to create an ecosystem around CEA innovation with some leading-edge projects in waste recycling, nutrient management, imaging and data analysis, and biotechnology. All of this will be facilitated by the  We have lots of exciting research projects happening at the moment, both internally to fuel innovation, as well as contract research to support and help solve industry challenges. There are a couple I can mention.

We have lots of exciting research projects happening at the moment, both internally to fuel innovation, as well as contract research to support and help solve industry challenges. There are a couple I can mention. When we launched the Center, one of the many opportunities we were excited about was our ability to leverage our state-of-the-art conferencing center here at IALR to bring industry and academia together through hosting conferences and workshops focusing on CEA. With the CEA industry growing in Virginia, the location of the Summit is near the stakeholders that the Center is striving to serve.

When we launched the Center, one of the many opportunities we were excited about was our ability to leverage our state-of-the-art conferencing center here at IALR to bring industry and academia together through hosting conferences and workshops focusing on CEA. With the CEA industry growing in Virginia, the location of the Summit is near the stakeholders that the Center is striving to serve. The CEA Innovation Center is growing rapidly, and we are always on the lookout for mutually beneficial partnerships in research and education, including contract research opportunities.

The CEA Innovation Center is growing rapidly, and we are always on the lookout for mutually beneficial partnerships in research and education, including contract research opportunities.

From the recent opening of its largest, most technologically advanced sustainable commercial smart farm in Bethlehem, Pennsylvania to its expansion into fruiting and vine crops with the launch of new strawberry varieties ,

From the recent opening of its largest, most technologically advanced sustainable commercial smart farm in Bethlehem, Pennsylvania to its expansion into fruiting and vine crops with the launch of new strawberry varieties ,  Investment in CEA comes down to two words: resiliency and sustainability. The past two years have made it painfully clear that climate change, global events, and supply chain disruption all have an enormous impact on our food systems. We need resiliency now more than ever before. By growing indoors, 365 days a year, with zero impact from drought, wildfires, or extreme temperatures, Bowery is growing a resilient supply of pesticide-free produce. And not only resilient, but predictable and reliable—we know, and therefore retailers know, exactly how much produce to expect, which cuts down on food waste.

Investment in CEA comes down to two words: resiliency and sustainability. The past two years have made it painfully clear that climate change, global events, and supply chain disruption all have an enormous impact on our food systems. We need resiliency now more than ever before. By growing indoors, 365 days a year, with zero impact from drought, wildfires, or extreme temperatures, Bowery is growing a resilient supply of pesticide-free produce. And not only resilient, but predictable and reliable—we know, and therefore retailers know, exactly how much produce to expect, which cuts down on food waste.

Bethlehem represents the next chapter in climate-smart agriculture at Bowery. The Bethlehem Farm, once a non-arable industrial site, is now modern farmland. This transformation from brownfield to vertical farm means that fresh, healthy food is now being grown, year-round, where it was previously thought no food would ever grow again.

Bethlehem represents the next chapter in climate-smart agriculture at Bowery. The Bethlehem Farm, once a non-arable industrial site, is now modern farmland. This transformation from brownfield to vertical farm means that fresh, healthy food is now being grown, year-round, where it was previously thought no food would ever grow again. Over the course of my career, so many talented women leaders helped shape and inspire my path. I wouldn’t be where I am today without their encouragement and support. This background, where women fiercely support one another, led me to co-found aGirlculture at Bowery. The group brings together women of all levels to connect with peers and senior leaders. We’re creating a space for mentorship and other opportunities for personal and professional growth.

Over the course of my career, so many talented women leaders helped shape and inspire my path. I wouldn’t be where I am today without their encouragement and support. This background, where women fiercely support one another, led me to co-found aGirlculture at Bowery. The group brings together women of all levels to connect with peers and senior leaders. We’re creating a space for mentorship and other opportunities for personal and professional growth. The Bethlehem Farm, our Smart Farm of the Future, is a model for what’s next at Bowery. We have two additional farms under construction in Locust Grove, Georgia and Arlington, Texas and we’re on track to double our number of farms by 2023, with the goal of helping to alleviate the strains insecurity puts on the U.S. food supply and economy.

The Bethlehem Farm, our Smart Farm of the Future, is a model for what’s next at Bowery. We have two additional farms under construction in Locust Grove, Georgia and Arlington, Texas and we’re on track to double our number of farms by 2023, with the goal of helping to alleviate the strains insecurity puts on the U.S. food supply and economy.

We differentiate ourselves from Shipping Container Farm businesses (

We differentiate ourselves from Shipping Container Farm businesses ( This process has inspired our vision to build a large scale production farm with groups of grow rooms that work together to grow a variety of crops under one roof – this might mean a warehouse farm with grow rooms built out and/or continuing to utilize shipping containers for this purpose (indoor or outdoors – or a combo of both). We are in the early stages of raising a Series A to build 15-20 grow rooms under one room with the addition of automation to begin to fulfill the demand in South Florida.

This process has inspired our vision to build a large scale production farm with groups of grow rooms that work together to grow a variety of crops under one roof – this might mean a warehouse farm with grow rooms built out and/or continuing to utilize shipping containers for this purpose (indoor or outdoors – or a combo of both). We are in the early stages of raising a Series A to build 15-20 grow rooms under one room with the addition of automation to begin to fulfill the demand in South Florida.  Cheryl and I started in one shipping container farm that we built ourselves (with the designer) – and did it all ourselves for the first 2 years – we acquired hands-on experience growing as well as all the different aspects involved with growing and distributing food; integrated technology, tested different crops, sales, marketing, distribution, accounting, packaging, food safety, etc. Most importantly, we were able to test the market which is the framework for building the business.

Cheryl and I started in one shipping container farm that we built ourselves (with the designer) – and did it all ourselves for the first 2 years – we acquired hands-on experience growing as well as all the different aspects involved with growing and distributing food; integrated technology, tested different crops, sales, marketing, distribution, accounting, packaging, food safety, etc. Most importantly, we were able to test the market which is the framework for building the business.  When we started Imagine Farms we appreciated the positive attributes that come with growing in a controlled environment; significant decrease in water usage when compared to field farming, growing without pesticides, and the positive aspects of ‘farm to table’ as a service. Now, it is evident that natural resources are scarce – specifically water, arable farmland and access to minerals for fertilizer.

When we started Imagine Farms we appreciated the positive attributes that come with growing in a controlled environment; significant decrease in water usage when compared to field farming, growing without pesticides, and the positive aspects of ‘farm to table’ as a service. Now, it is evident that natural resources are scarce – specifically water, arable farmland and access to minerals for fertilizer.  We are facing a grain shortage that will drive up the cost of basic food and other commodities because of the war in Ukraine, while our physical resilience and mental health depend on access to fresh, healthy food. The more intelligent, motivated and passionate individuals exposed to the industry, the better. Shipping container farms placed in schools, universities, public programs and start-ups might be the greatest vehicle to accelerate this industry.

We are facing a grain shortage that will drive up the cost of basic food and other commodities because of the war in Ukraine, while our physical resilience and mental health depend on access to fresh, healthy food. The more intelligent, motivated and passionate individuals exposed to the industry, the better. Shipping container farms placed in schools, universities, public programs and start-ups might be the greatest vehicle to accelerate this industry.

For farmers. By farmers. That’s how

For farmers. By farmers. That’s how

This was mainly to help us grow a team, open two new offices (Hello Austin!) and to market ourselves in the industry. We are also aware that large farming projects can take months to get going, so we also have some operating capital to ensure we are able to grow for years to come.

This was mainly to help us grow a team, open two new offices (Hello Austin!) and to market ourselves in the industry. We are also aware that large farming projects can take months to get going, so we also have some operating capital to ensure we are able to grow for years to come.